Quality Parts Made Easier, Faster

Create high-quality molding fast and affordably with NeedMold. Choose from multiple capabilities, mateirals, and surface finishes. Get instant quotes with our lightning-fast quoting platform. Your ideal partner for custom molded parts.

35+ surface finishes, 80+plastics&Metal

Instant quotes for 1-1,0000 parts

20% off or more affordable pricing

Our Manufacturing Capabilities

Needmold provides a range of manufacturing capabilities to support rapid prototyping and both low and high-volume production needs. With our own factory and a reliable Chinese network, we deliver complex, high-quality parts efficiently.

Plastic injection molding, rapid and production tooling, overmolding,and insert molding. No MOQ required, all while maintaining consistent quality.

T1 samples as fast as 2 weeks

1 to 1M pcs

Choose from Aluminum, Zinc, Magnesium, Copper. High precision die cast metal parts for high-volumeneeds.

Minimum batch: 1000 pcs

Minimum wall thickness: 0.03 in. (0.8 mm)

We specialize in extruding aluminumprofiles. Offer high quality, low-costmetal extrusions with a variety of post-machining options.

Lead times from 2 weeks

Design and manufacturing of molds for small accessories of household appliances

Precison to reach +0.008in (0.2 mm)

Lead time: Up to 20 parts in 15 days or less

Injection Molds for Automotive Window Lift Plastic Components

Precison to reach +0.008in (0.2 mm)

Lead times from 3 days

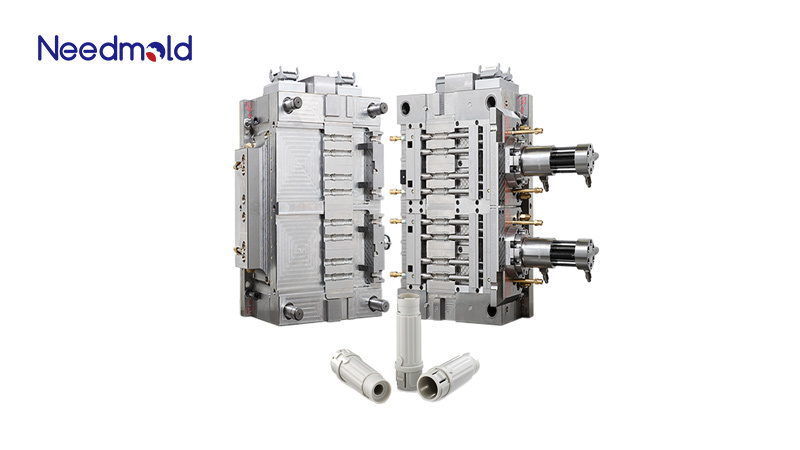

Injection Molds for Embedded Brass Inserts & Metal Components

Tolerances as tight as +0.001in (0.025 mm)

Wall thickness as thin as 0.020 in (0.5 mm)

Bristle Brick mold and molding service Bristle Brick Mold: Technical Challenges and Manufacturing Process

Small parts tolerance down to+0.02in(+0.5 mm)

Kerf width typically ranges from0.001in.to 0.01in.

SLA,HP MJF,SLS,SLM technologiesfor functional prototyping and low-volume production. We manufacture3d printed parts at competitive price.

Tolerances as fine as +0.008 in (±0.2 mm)

Metal and plastic 3D printing

Lead times from 1 day

China-Based Expansive Manufacturing Network

Needmold owns factories and works with highly vetted partners in China. This extensive network allows for fast production and scalable capabilities for custom plastic and metal parts, ensuring high quality and reliability for all your projects.

Machines Set

Tight Tolerance

Fast Lead Time

Launch Your Next Big Idea. Easier, Faster

Needmold streamlines every stage of your product journey — from concept , prototyping, to mass production.

production, assembly, and packaging. Get fast, dependable, and budget-friendly solutions, all with great quality and flexible delivery.

Your Trusted Partner for High-quality Manufacturing

Quality is at the core of everything we do at Needmold. We ensure accuracy and precision in every step of the production process.

By utilizing advanced inspection equipment such as CMM, two-dimensional measuring instruments, XRF analyzers, gauges, micrometers, and calipers, we provide you with peace of mind and assurance that your parts are the quality you expect and demand.

Our experienced quality team applies rigorous control measures with on-site inspections at every phase—pre-production, in-production, and final production. These inspections focus on appearance, functionality, and specific requirements. We also provide detailed reports as needed, including first article inspections, RoHS compliance, and visual, dimensional, and performance assessments.

Over the past 20 years, we’ve earned multiple ISO certifications demonstrating our quality capabilities. We guarantee timely and reliable prototyping and production services.

20+ inspection equipment

30+ quality engineers

ISO 9001:2015, ISO 13485, ISO 14001, and IATF 16949

Blog

Welcome to our blog for insights into different manufacturing processes.