Custom CNC Machining Services

Accelerate prototyping, product development and production with a faster,

easier way to get precision CNC machined parts with tolerances as tight as ±0.0001 inch.

CNC parts manufactured as fast as 1 day with 95.4% of orders delivered on-time and in-full.

Join 5,000+ companies who work with Needmold

ISO 9001:2015 certified QMS

45+ Certified Materials, 13+ Finishing Options

NADCAP and NABL approved manufacturing partners

Hand Metrology, Laser & CMM Inspections

Hardware Installation & Mechanical Assembly

Our CNC Machining Services

CNC Milling

3, 4 and 5-axis machining capabilities for simple and complex geometries.

CNC Turning

Standard and live tooling capabilities for cylindrical parts such as pins, shafts, and spacers.

Electrical Discharge Machining (EDM)

Wire and Sinker EDM are non-contact machining methods for cutting deep pockets, complex internal features, and holes with a keyway.

Gear Hobbing

A wide range of stock hobbing tools available for quick turnaround times.

Large CNC Parts

Custom large CNC parts at scale, ensuring you receive repeatability, quality to you.

Precision Machining Tolerance

| Metals, PEEK, And ULTEM with Drawing |

Other Plastics with Drawing |

No Drawing | |

| Linear Dimension | +/- 0.0025 mm +/- 0.0001 inch |

+/- 0.05 mm

+/- 0.002 inch |

ISO 2768 Medium |

| Hole Diameters (Not Reamed) |

+/- 0.0025 mm

+/- 0.0001 inch |

+/- 0.05 mm +/- 0.002 inch |

ISO 2768 Medium |

| Shaft Diameters | +/- 0.0025 mm

+/- 0.0001 inch |

+/- 0.05 mm

+/- 0.002 inch |

ISO 2768 Medium |

Part lengths of up to 48" are available on our platform process dependent. Please inquire about anything larger. Tolerances listed here are minimums for an ideal case. Looser tolerances may be required depending on process, material choice, or part geometry.

Get Instant CNC QuoteCNC Machining Materials

A2 Tool Steel

ABS

Acrylic

Aluminum

Brass

Bronze

Cast Iron

Copper

Delrin

Garolite G-10

HDPE

Invar

Kovar

Magnesium

Nylon

PEEK

Polycarbonate

Polypropylene

PPS

PTFE

PVC

Stainless Steel

Steel

Titanium

Tool Steel

Torlon

UHMW

Ultem

Zinc

A2 Tool Steel

Tool Steel has excellent wear resistance and toughness, commonly used to make fixtures, tools, tool holders, gauges, and punches.

|

Mill Lead Time: |

As fast as 7 days |

| Finishing Options: | Media Blasting, Vibratory Tumbling, Black Oxide, Powdercoating |

ABS

ABS (Acrylonitrile Butadiene Styrene) is an affordable thermoplastic that has become popular for pre-injection molding prototypes. It is a versatile material known for its strength, durability, and resistance to impact and heat. ABS plastic is widely used in the automotive and consumer electronics industries due to its excellent mechanical properties and ease of processing. Additionally, it can be easily modified with other additives to enhance specific properties such as flame retardancy or UV resistance.

| Mill Lead Time: | As fast as 3 days |

| Colors: | Black, neutral matte finish |

Acrylic

Acrylic is a durable plastic material that is resistant to scratches, making it an ideal choice for various applications such as tanks, panels, and optical displays. It is also lightweight and shatter-resistant, which makes it a popular alternative to glass. Acrylic is known for its clarity and transparency, making it a great option for applications where optical performance is important. Additionally, it can be easily fabricated into different shapes and sizes, allowing for a wide range of design possibilities.

|

Mill Lead Time: |

As fast as 3 days |

|

Colors: |

Optically clear, opaque |

Aluminum

Aluminum is a lightweight and highly versatile material that is widely used in various industries. It offers a unique combination of properties including high strength-to-weight ratio, excellent corrosion resistance, malleability, and good thermal and electrical conductivity. These characteristics make aluminum an ideal choice for applications where weight reduction, durability, and efficient heat transfer are important factors, like engine blocks, heat exchangers, and other transportation components.

|

Mill Lead Time: |

As fast as 3 days |

| Alloys: | 6061-T6, 7075-T6, 7050, 2024, 5052, 6063, MIC6 |

| Finishing Options: | Alodine, Anodizing Types II, III, III + PTFE, ENP, Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing. |

Brass

360 Brass (free-machining brass) is a versatile material for various industries. Common applications include gears, lock components, pipe fittings, and decorative parts. It has excellent machinability and can be easily fabricated into different shapes and sizes. It boasts high corrosion resistance and good electrical conductivity, making it an ideal choice for electrical components and marine applications.

|

Mill Lead Time: |

As fast as 5 days |

| Finishing Options: | Media blasting |

Bronze

932 Bearing Bronze is a reliable and robust, providing excellent wear and corrosion resistance due to its tin, iron, and zinc content. It’s a great choice for applications requiring good wear and corrosion resistance. This alloy is commonly used in applications that require high strength, low friction, and resistance to wear and tear. Because of its strength and durability, it is an ideal choice for bearings, bushings, thrust washers, valve components, and other parts subjected to heavy loads or harsh environments.

|

Mill Lead Time: |

As fast as 5 days |

| Finish Options: | Available as-machined, media blasted, or hand-polished |

Cast Iron

Cast Iron is a material known for its durability and wear resistance, making it an excellent choice for absorbing vibrations. It is commonly used in various industrial applications such as gears, bases, pulleys, and bushings. Due to its ability to withstand high levels of stress and pressure, cast iron is often preferred over other materials in heavy-duty machinery and equipment. Its unique properties make it a reliable option for industries that require stable and long-lasting components.

|

Mill Lead Time: |

As fast as 7 days |

|

Finish Options: |

Media blasting, Tumbling |

Copper

Copper 101 and 110 have unmatched thermal and electrical conductivity, which makes them a popular choice for bus bars, wire connectors, and other electrical applications like parts for power transmission and distribution systems. Copper alloys 101 and 110 also offer incredible durability, corrosion resistance, and ease of fabrication. Commonly used in high-performance electrical components such as transformers, generators, motors, and switchgear.

|

Mill Lead Time: |

As fast as 3 days |

|

Finishing Options: |

Available as-machined, media blasted, or hand-polished |

|

Alloys: |

101, 110 |

Delrin

Delrin (acetal) is a plastic with low friction and high stiffness. Delrin has exceptional dimensional accuracy, making it an ideal choice for applications where precision is critical. It also has relatively high toughness which makes it resistant to impact and wear. Delrin’s minimal elongation means it can maintain its shape under stress without significant deformation. Delrin is commonly used in a variety of industries such as automotive, aerospace, and consumer goods.

|

Mill Lead Time: |

As fast as 3 days |

|

Colors: |

White, black, brown |

|

Grades: |

150, AF (13% PTFE Filled), 30% Glass Filled |

Garolite G-10

Garolite G-10 is a high-pressure laminate material composed of layers of woven fiberglass cloth impregnated with epoxy resin. It is a strong and rigid material that exhibits excellent electrical insulation properties, along with water resistance. Garolite G-10 is known for its high mechanical strength and dimensional stability. It is commonly used in insulating components, circuit boards, and other electrical components. G-10 is a composite material with a low coefficient of thermal expansion.

|

Mill Lead Time: |

As fast as 7 days |

|

Colors: |

Green, yellow |

HDPE

High-density polyethylene (HDPE) is a versatile thermoplastic known for its durability, chemical resistance, impact resistance, structural integrity, and low moisture absorption. It is commonly used in packaging, construction, and automotive manufacturing industries. Other applications include plugs and seals. It is also an excellent electrical insulator.

|

Mill Lead Time: |

As fast as 3 days |

|

Colors: |

White, black |

Invar

Invar is a Ni-Fe alloy with high dimensional accuracy and excellent thermal dimensional stability. It is commonly used in industries such as aerospace, electronics, and precision engineering. Common applications include precision instruments and devices where temperature-dimensional changes are undesirable. It is ideal for components such as clock pendulums, bi-metallic strips, and measuring instruments. In the aerospace industry, Invar is used in satellite structures, antennas, and optical systems.

|

Processes: |

CNC Mill CNC Lathe |

|

Mill Lead Time: |

As fast as 7 days |

|

Finishing Options: |

Vibratory Tumbling, Media Blasting, Powdercoating |

|

Tolerance: |

With drawing: as low as +/- 0.005 mm No drawing: ISO 2768 medium |

Kovar

Kovar is a Ni-Fe-Co alloy known for its excellent thermal expansion properties and dimensional stability. It is commonly used for electronics, telecommunications, and aerospace components, such as hermetic seals for devices like vacuum tubes and transistors, telecommunications equipment, and turbine blades. Its ability to nearly match the coefficient of thermal expansion of glass enables airtight sealing, preventing moisture or contaminants from damaging sensitive electronic components.

|

Processes: |

CNC Mill CNC Lathe |

|

Mill Lead Time: |

As fast as 7 days |

|

Finishing Options: |

Vibratory Tumbling, Media Blasting, Powdercoating |

| Tolerance: | With drawing: as low as +/- 0.005 mm No drawing: ISO 2768 medium |

Magnesium

Magnesium has an excellent strength-to-weight ratio. It is widely used in industries such as automotive, aerospace, and electronics. Common applications include lightweight components that help improve fuel efficiency and reduce emissions, aircraft structures and components, engine blocks, transmission cases, and wheels. The high strength allows weight savings without losing performance or safety. Its low density makes it highly desirable for reducing weight in airplanes and spacecraft.

|

Processes: |

CNC Mill CNC Lathe |

|

Mill Lead Time: |

As fast as 10 days |

|

Finishing Options: |

Vibratory Tumbling, Media Blasting, Powder Coating |

|

Tolerance: |

With drawing: as low as +/- 0.005 mm No drawing: ISO 2768 medium |

Nylon

Nylon is thermoplastic with high strength, wear resistance, excellent sound/vibration dampening, and low friction coefficient. It is commonly used in engineering and manufacturing processes. Common applications include gears, bearings, and bushings. Two of the most notable use cases for Nylon are in medical devices and electronics insulation, notably screws and spacers for panel mounted circuit boards.

| Mill Lead Time: | As fast as 3 days |

PEEK

PEEK, (polyether ether ketone) is a thermoplastic widely used in industries such as aerospace, automotive, and electronics. PEEK has high strength, stiffness, toughness, chemical, biocompatibility, and thermal resistance. Due to its , PEEK is also suitable for use in harsh environments where other materials may fail. Common applications include aircraft structures, electronic components that require high temperature resistance, and medical and dental components (including implantables).

|

Mill Lead Time: |

As fast as 3 days |

| Colors: | Opaque beige |

| Grades: | Standard PEEK, 30% Glass Filled |

Polycarbonate

Polycarbonate is a durable and transparent thermoplastic with good electrical insulation, heat resistance, impact resistance, clarity, flame retardancy, and scratch resistance. Common applications include safety glasses, protective shields, electrical enclosures, connectors, and insulators. It is one of the most commonly utilized plastics in manufacturing.

|

Mill Lead Time: |

As fast as 3 days |

| Colors: | Clear, black and glossy |

Polypropylene

Polypropylene (PP) is a thermoplastic that has a high melting point, high strength-to-weight ratio, and excellent chemical resistance, durability, reliability, moisture resistance, and fatigue strength. Common applications include laboratory equipment, medical devices, food processing equipment, consumer goods, aircraft interior components, ducting, housings, automotive bumpers, fuel tanks, and battery cases.

|

Mill Lead Time: |

As fast as 3 days |

|

Colors: |

White (semi-clear or opaque) |

PPS

Polyphenylene Sulfide (PPS) is a thermoplastic with exceptional chemical resistance, thermal stability, high-temperature resistance, chemical resistance, dimensional stability, and electrical insulation. Common applications include automotive components, electrical connectors, and industrial equipment, such as fuel systems, turbine blades, brake pads, bearings, gears, switches, and engine components. PPS parts remain durable and reliable even in harsh environments.

|

Mill Lead Time: |

As fast as 7 days |

|

Colors: |

Natural (off-white) |

PTFE

PTFE (Teflon™, polytetrafluoroethylene) has low friction nonstick properties, excellent chemical resistance, high temperature resistance, and electrical insulating properties. It is commonly utilized in low-friction applications such as bearings, seals, gaskets, bearing, and washers. It is also good for parts that require insulating properties.

|

Mill Lead Time: |

As fast as 3 days |

|

Colors: |

Black, white (opaque) |

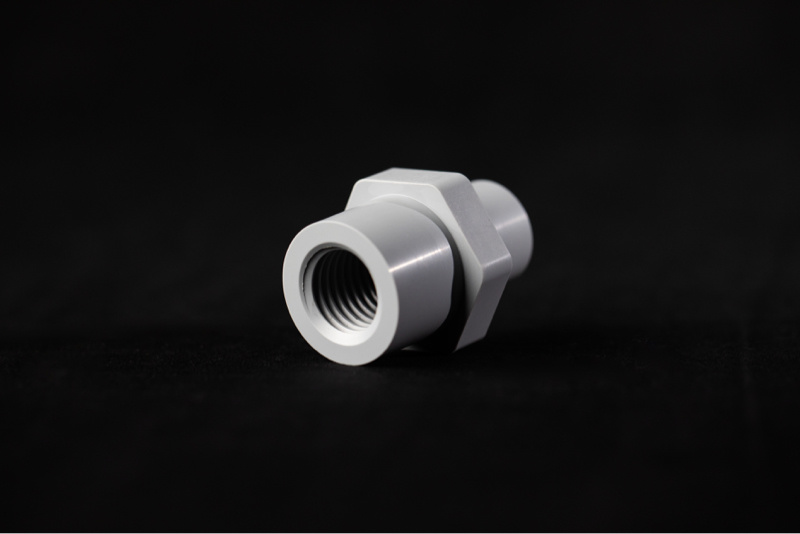

PVC

PVC (Polyvinyl chloride) is a plastic with high durability and versatility, excellent chemical and UV and corrosion resistance. Common applications include pipes, fittings, electrical enclosures, tubing, automotive interior, and commercial building components. It is cost-effective and lightweight, with a long lifespan.

|

Processes: |

CNC Mill CNC Lathe |

|

Mill Lead Time: |

As fast as 5 days |

|

Finishing Options: |

Available as-machined |

|

Tolerance: |

With drawing: as low as +/- 0.005 mm No drawing: ISO 2768 medium |

Stainless Steel

Stainless Steel is a popular and highly versatile material known for its exceptional strength, and durability, along with high temperature, and corrosion resistance. It is widely used in industries such as construction, automotive, aerospace, and manufacturing, with applications ranging from heat exchangers, industrial ovens, exhaust systems, construction equipment, heavy machinery, engine components, fasteners, turbine blades, tanks, pumps, valves, orthopedic implants, and medical equipment.

|

Mill Lead Time: |

As fast as 7 days |

|

Finishing Options: |

Black Oxide, Electropolishing, ENP, Media Blasting, Nickel Plating, Passivation, Powder Coating, Tumble Polishing, Zinc Plating, Vibratory Tumbling |

|

Alloys: |

303, 304L, 316L, 410, 416, 440C, 17-4PH, Nitronic 60 |

Steel

Fictiv offers a wide range of steel options to meet the demands of various applications. Alloy and carbon steel are particularly useful for creating fixtures, mounting plates, draft shafts, axles, torsion bars, gears, bolts, studs, shafts, and structural components. High-quality steel materials provide excellent strength and durability, making them ideal for demanding industrial applications.

|

Mill Lead Time: |

As fast as 7 days |

| Alloys: | 4140, 4130, A514, 4340 |

| Carbon Steel Types: | 1018 Low Carbon, 1045 Carbon, Galvanized Low-Carbon |

| Finishing Options: | Black Oxide, ENP, Electropolishing, Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing, Zinc Plating, Vibratory Tumbling |

Titanium

Titanium is lightweight, strong, biocompatible, and highly resistant to corrosion. It has a high strength-to-weight ratio and excellent temperature resistance. It is commonly used in industries such as aerospace and medical devices. It’s also used for parts like engine components, landing gear, structural elements, medical implants, and prosthetics. Other common use cases include aerospace fasteners, turbine blades, sports equipment, and marine applications.

|

Mill Lead Time: |

As fast as 7 days |

| Finishing options: | Media Blasting, Vibratory Tumbling, Passivation, Powdercoating |

| Grade: | Titanium Grade 5 |

Tool Steel

A2 Tool Steel has excellent wear resistance and toughness, commonly used to make fixtures, tools, tool holders, gauges, and punches.

|

Mill Lead Time: |

As fast as 7 days |

| Finishing Options: | Media Blasting, Vibratory Tumbling, Black Oxide, Powdercoating |

Torlon

Torlon is a thermoplastic with exceptional mechanical strength, heat resistance, and chemical resistance and reliable performance under extreme conditions. It’s an ideal choice for applications in industries such as aerospace, automotive, and oil and gas. Additionally, Torlon has excellent chemical resistance, making it suitable for use in harsh environments where exposure to chemicals and solvents is common.

|

Processes: |

CNC Mill CNC Lathe |

| Mill Lead Time: | As fast as 7 days |

| Finishing Options: | Available as-machined |

| Tolerance: | With drawing: as low as +/- 0.005 mm No drawing: ISO 2768 medium |

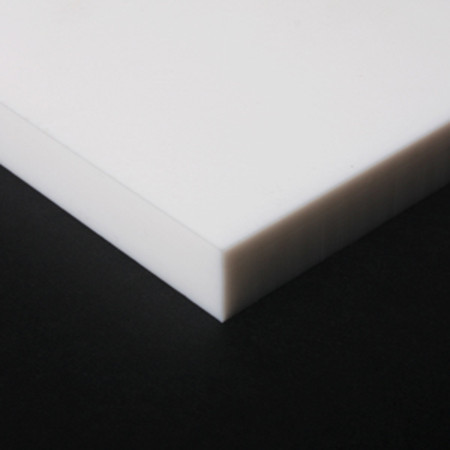

UHMW

Ultra-High-Molecular-Weight Polyethylene (UHMW) has high abrasion resistance, great durability, excellent wear resistance, low friction coefficient, and excellent impact strength. UHMW is also lightweight, self-lubricating, and has good chemical resistance. Common applications include gears, bearings, liners, conveyors, food processing, agriculture, and automotive components. Another advantage of UHMW is its ability to absorb shock.

|

Mill Lead Time: |

As fast as 3 days |

| Colors: | White, black |

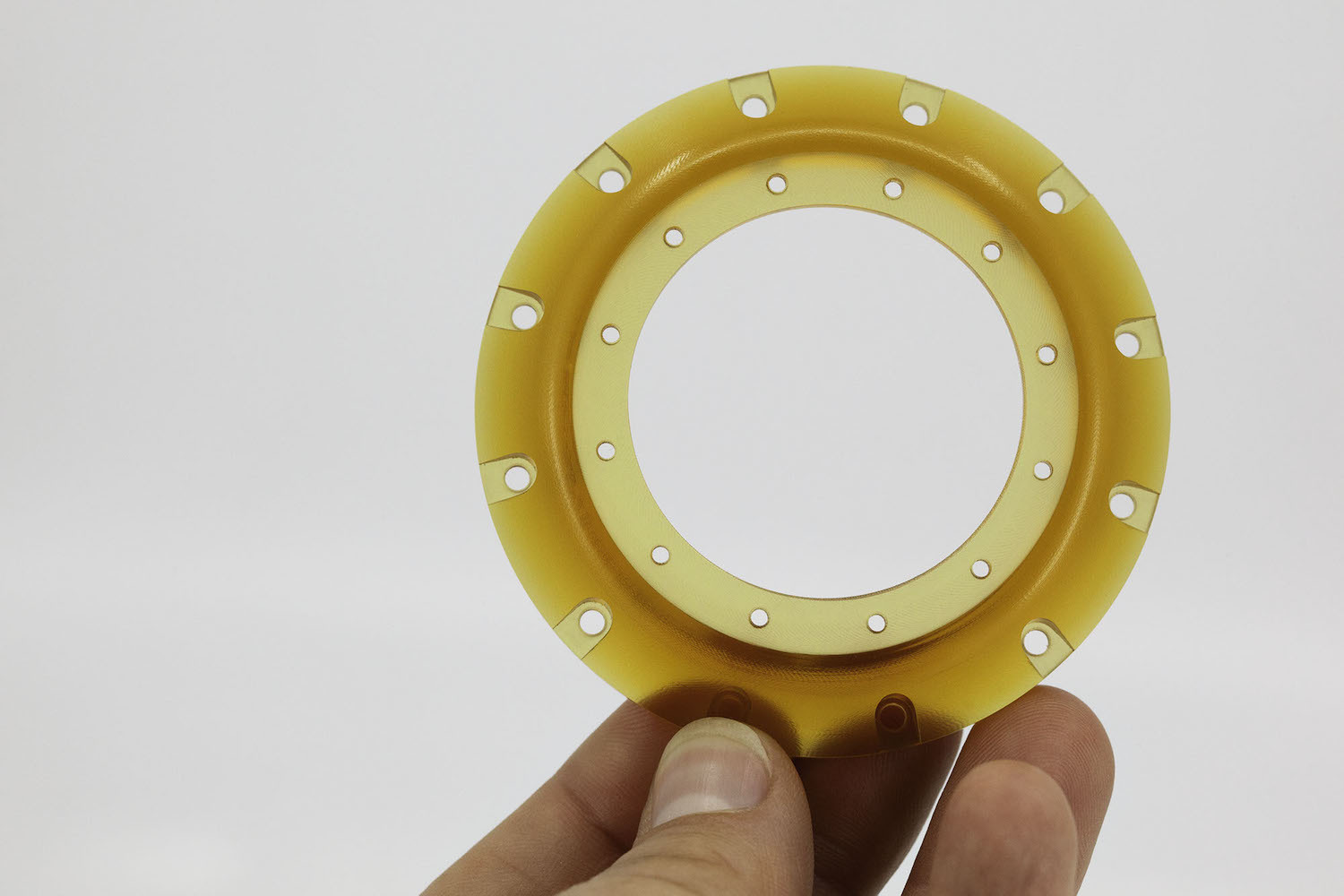

Ultem

ULTEM is a thermoplastic with exceptional strength, stiffness, durability, environmental resistance, heat resistance, low flammability, and excellent electrical insulation capabilities. Common applications include electronic components/connectors, industrial equipment, surgical instruments, aerospace engine components, and medical devices. In addition to its mechanical properties, ULTEM exhibits excellent chemical resistance, making it suitable for corrosive environments.

|

Mill Lead Time: |

As fast as 7 days |

|

Colors: |

Naturally translucent amber color, frosted when machined |

Zinc

Zinc is a versatile metal with excellent heat resistance, durability, strength, electrical conductivity, thermal conductivity, machinability, and corrosion resistance. Common applications include automotive parts such as gears, bushings, and bearings. Additional applications include door and window hardware, locks, and hinges, as well as electrical connectors and switches. It is also ideal for applications involving moisture exposure or other harsh environments.

|

Processes: |

CNC Mill CNC Lathe |

|

Mill Lead Time: |

As fast as 7 days |

|

Finishing Options: |

Vibratory Tumbling, Media Blasting, Powder Coating |

|

Tolerance: |

With drawing: as low as +/- 0.005 mm No drawing: ISO 2768 medium |

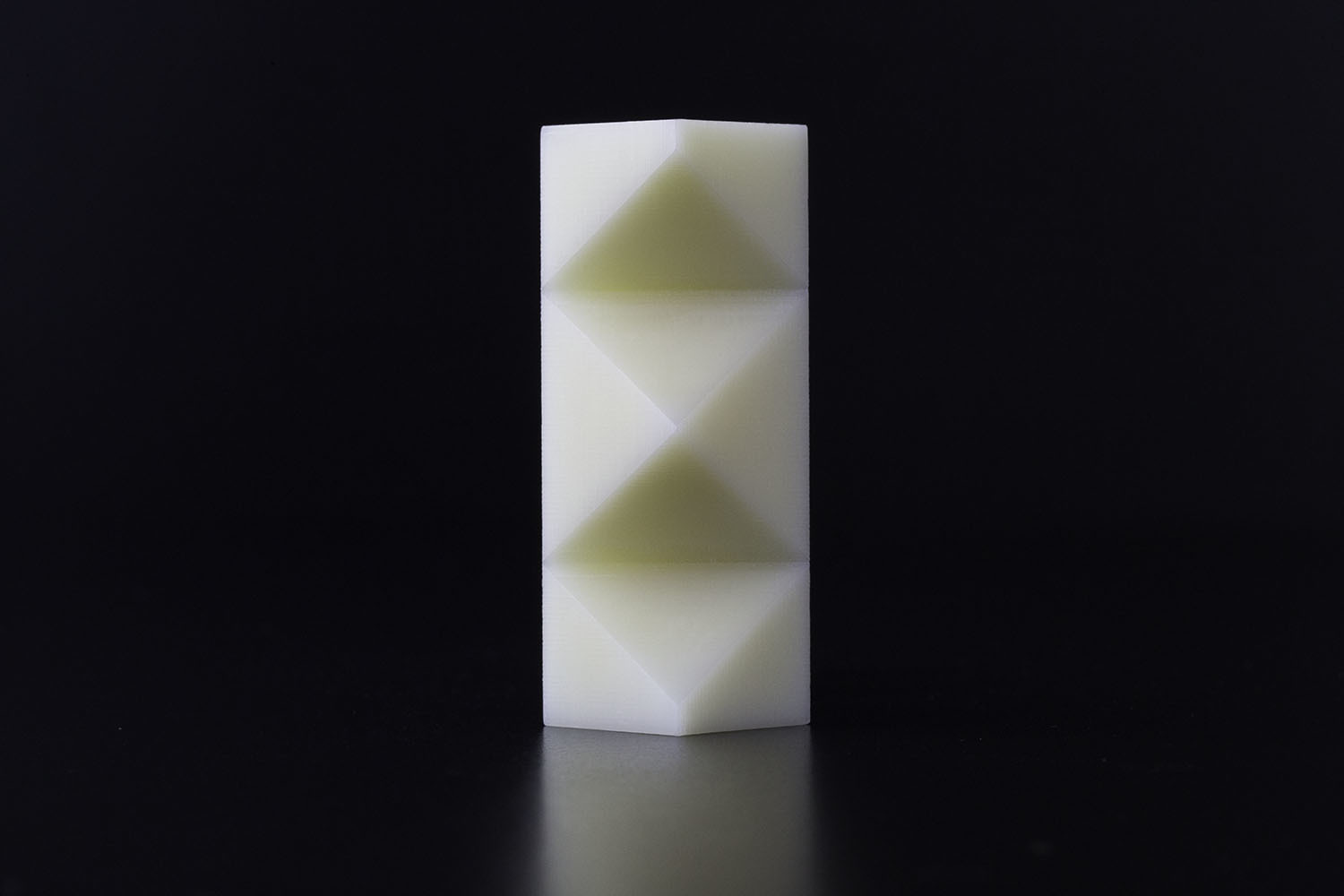

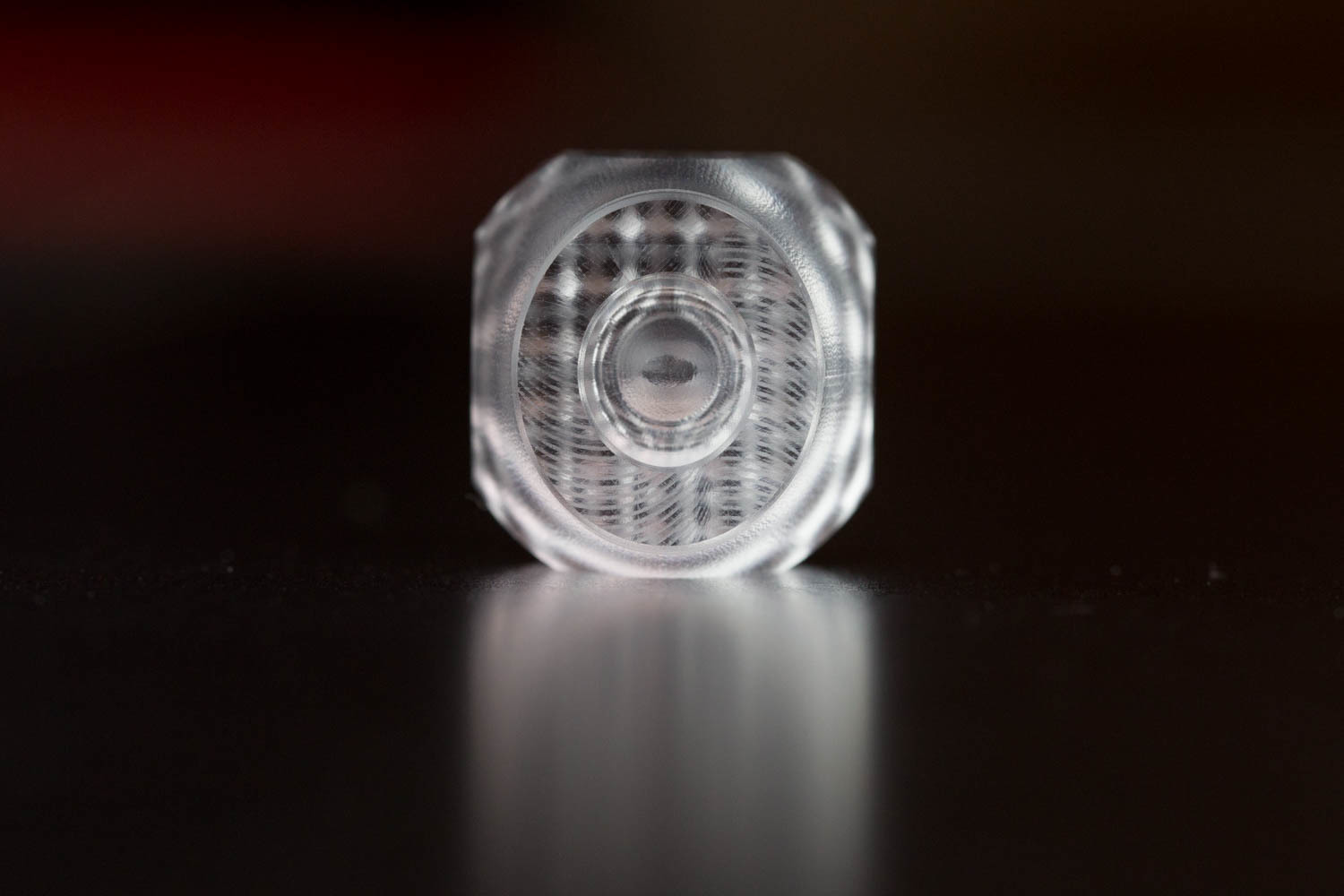

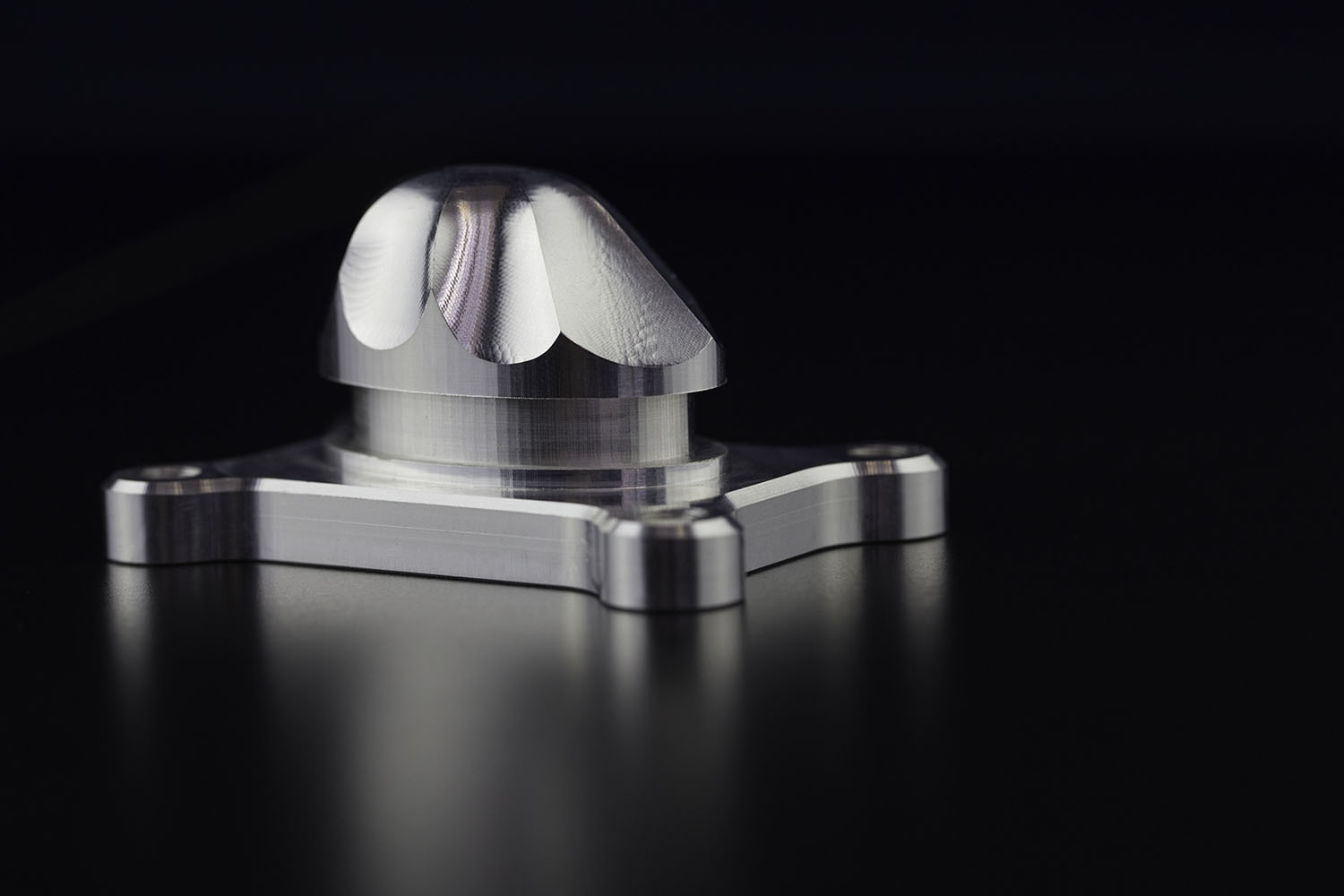

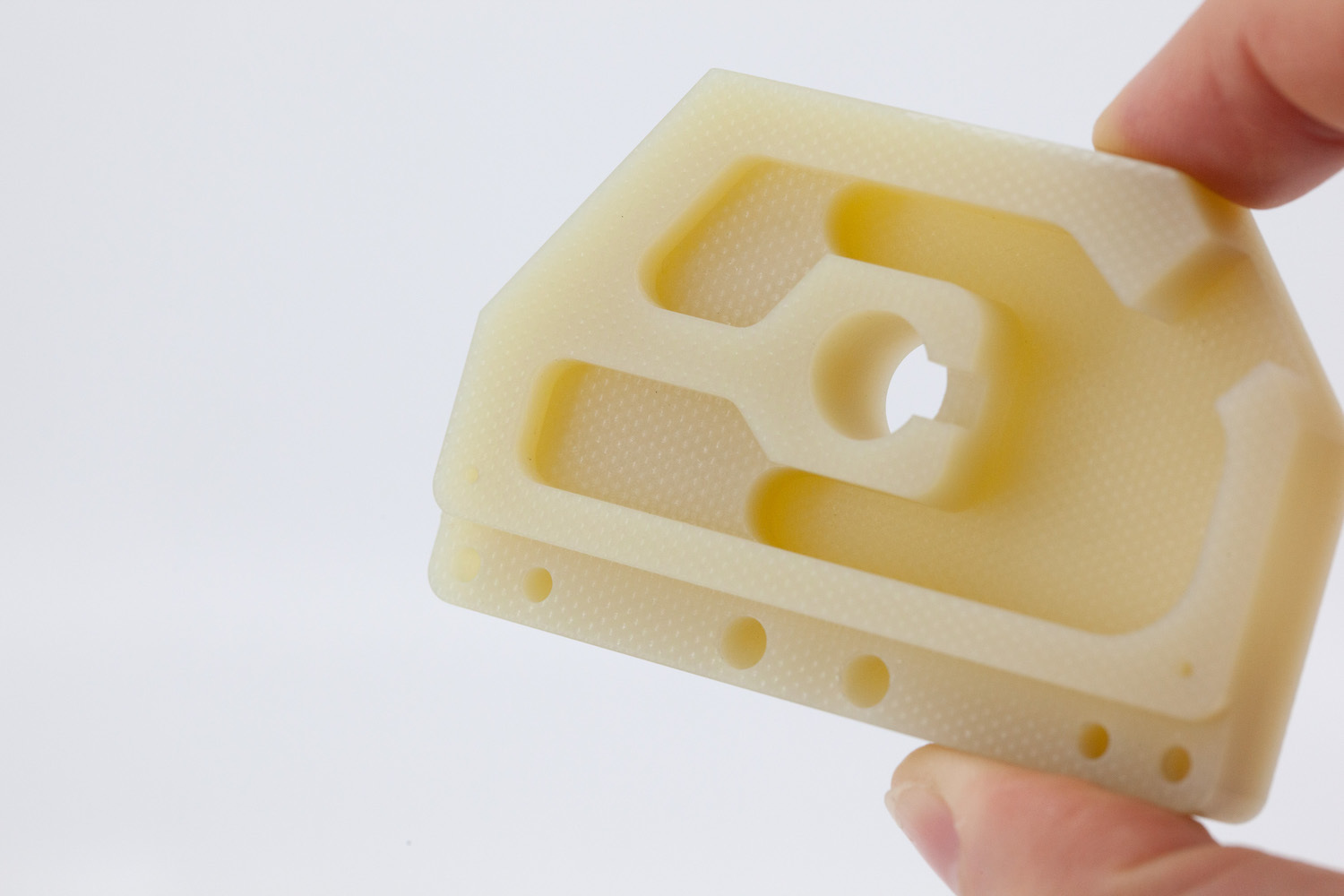

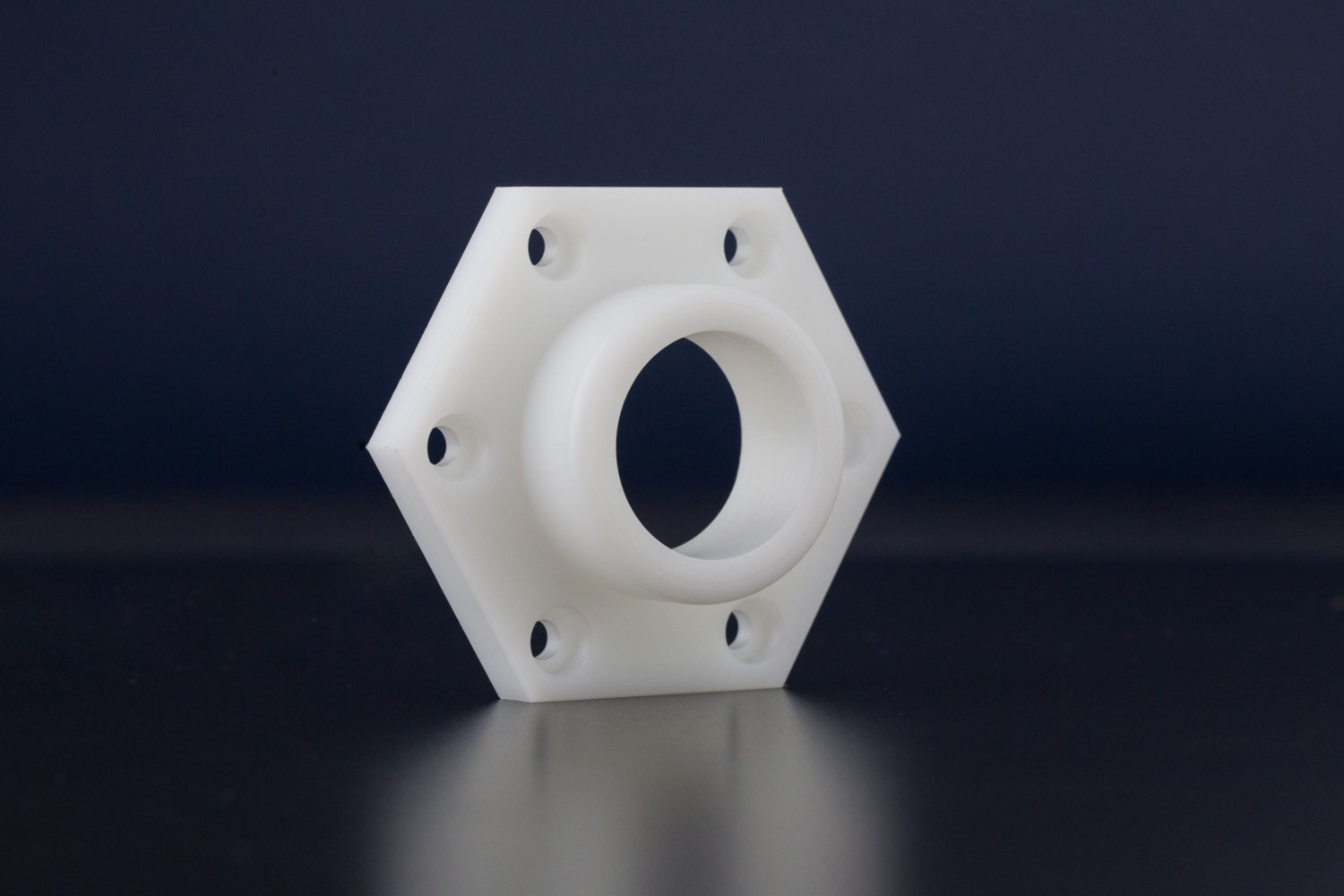

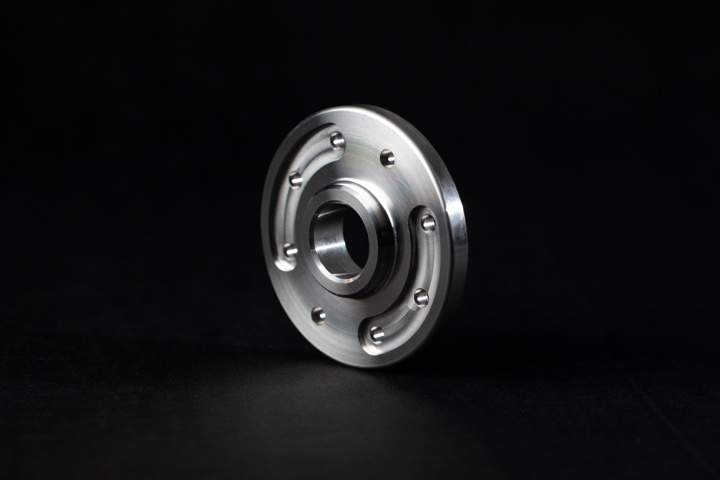

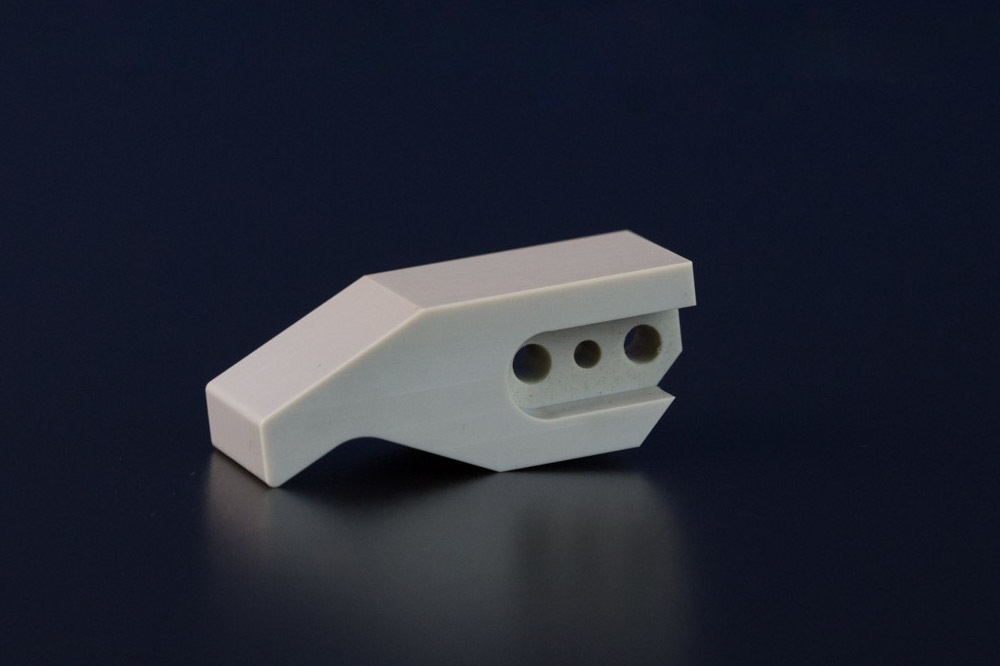

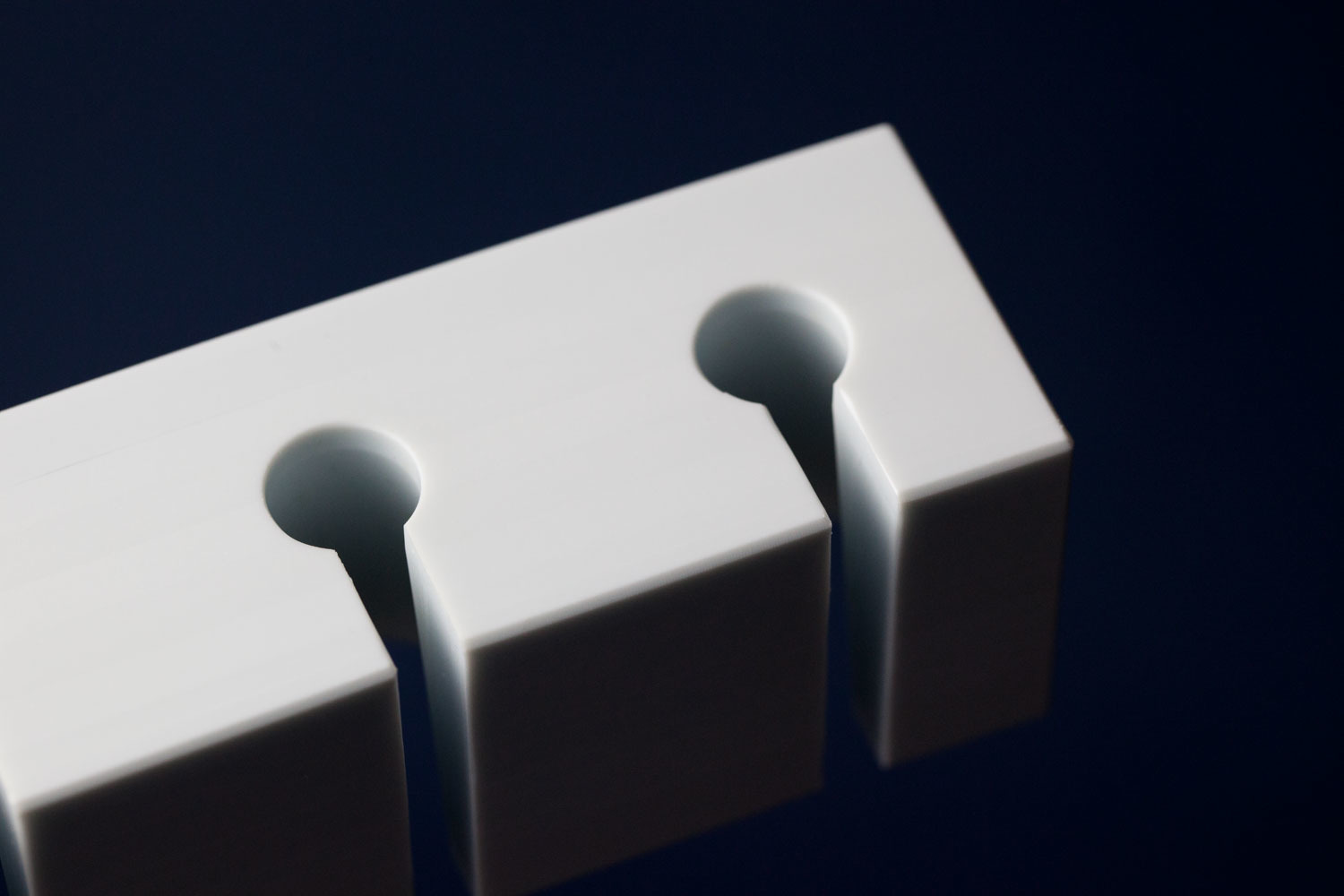

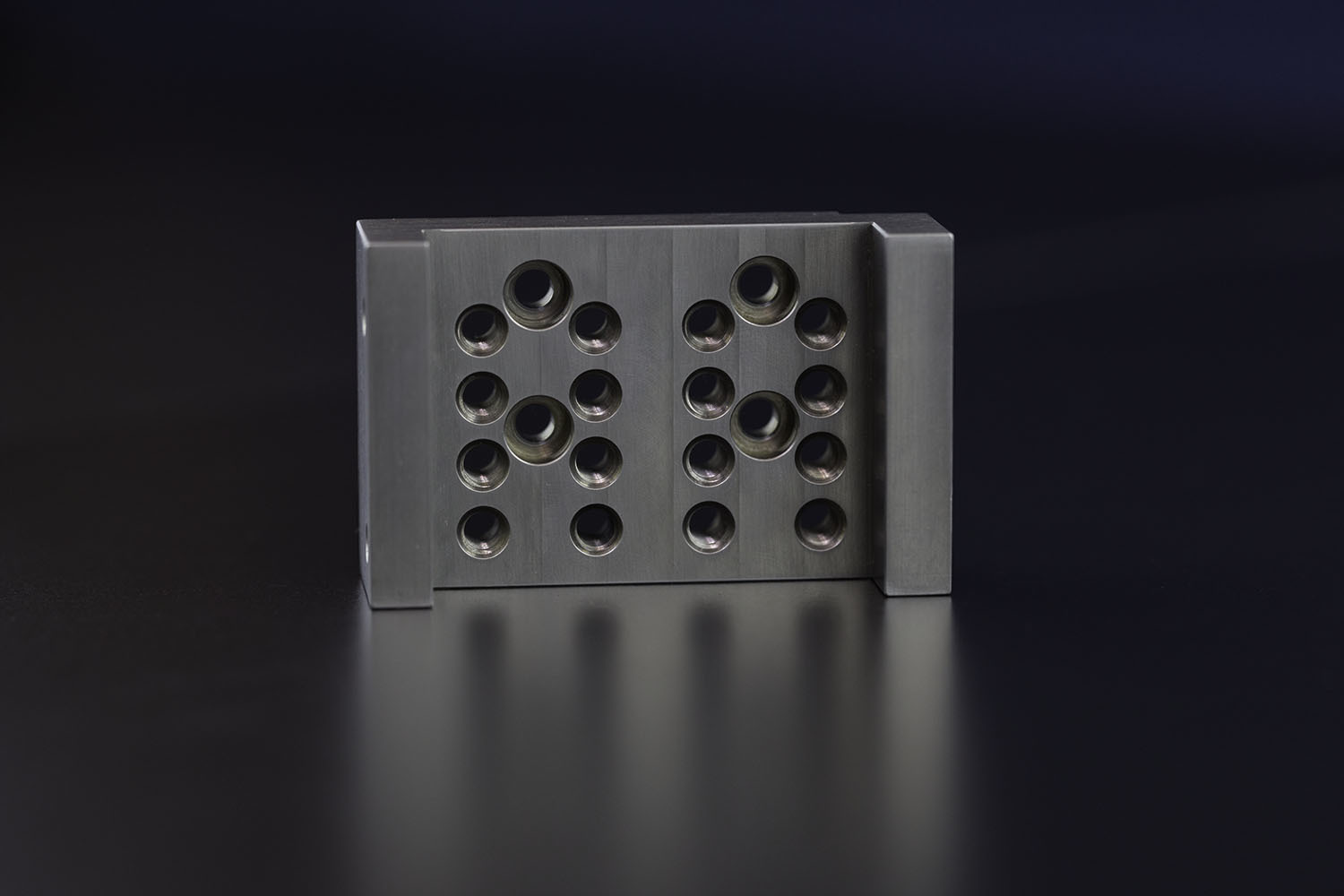

CNC Machining Parts Made By Needmold

CNC Machining Service FAQs

What certifications or industry standards do you adhere to in your CNC machining processes?

Needmold is ISO 9001 certified, ISO 13485 compliant, and has NADCAP and NABL approved manufacturing partners.

Can you assist with design optimization for manufacturability in CNC machining?

Our platform provides free Design for Manufacturability (DFM) feedback pre-order on all quotations. There are two categories of this feedback: 1. “Warning” indicates a design that requires a closer look, but can still proceed with ordering. 1. “Failure” indicates the component has a significant risk of failure during manufacturing. In this case, a design revision must be uploaded prior to check-out. We also have a team of engineers available to provide DFM feedback via email or phone.

Are you able to work with complex geometries or 2D drawings for CNC?

Needmold not only supports complex geometries, but we pride ourselves on being able to produce and deliver complex parts. Our platform enables 2D drawing uploads and generates 2D drawings. Our quoting engine then analyzes the drawings for configuration details and special callouts.

Can you accommodate rush orders or expedited delivery for CNC machining?

Speed is standard at Needmold. We offer a variety of costs and lead times to match your requirements. However, if you require faster delivery for a specific quote, please reach out to your sales representative to see if we can accommodate your request.

How do you ensure the confidentiality and security of our designs and intellectual property?

At Needmold, we know how critical information security is, especially when working with high-value design IP. That's why we designed our platform with elite-level security and confidentiality as a top priority. From log in to file upload to part fulfillment, you can rest easy knowing that your IP is safe within our secure Digital Manufacturing Ecosystem. Need extra assurance? We're happy to sign an NDA, simply fill out a request here.

What types of materials work with your CNC machining services?

Our instant quoted materials can be found here. Not seeing what you are looking for? You can always request a custom material through our custom RFQ process.

What tolerances can your CNC machines achieve?

Our machines are capable of tolerances as tight as +/- 0.0001 inches.

What is your typical lead time for CNC machining orders?

Needmold provides a variety of lead times to match your budget while maintaining your project timeline. We can supply CNC parts as quickly as two days.