Injection Molding Service

Needmold’s injection molding service delivers high-quality custom parts quickly and accurately, tailored to your requirements. A dedicated global team ensures full visibility and a smooth process from DFM to final delivery.

T1 samples as fast as 2 weeks

No minimum order quantities

Production-grade steel tooling

Rapid online quotes with free DFM feedback

Global Network - Domestic, Overseas, and Near Shore options

Injection Molding Tooling Table

| Prototype | Production | |

| Pre-Sale DFM/Asisstance |  |

|

| Parts to Print Tolerances |  |

|

| Mold Flow Analysis |  |

|

| Standard Finishes (SPI A1-D3 and VDI) |  |

|

| Custom Mold Textures (Mold-Tech, Yick Sang, others) |  |

|

| Thermoplastics (Commercial and Engineering Grade) |  |

|

| Automatic Lifters and Slides |  |

|

| Standard Gating (Direct, Edge, Fan, others) |  |

|

| Hot Runner and Manifold System |  |

|

| Sequential Valve Gating |  |

|

| Multi-Cavity Molds |  |

|

| Family Tooling |  |

|

| Class 102 and 103 Molds |  |

|

| Class 101 Molds |  |

|

| Press Sizes | 35 - 3,000 Tons | 150 - 3,000 Tons |

| Cycle Ranges | 1 - 100,000 | 1 - 1,000,000+ |

| T1 Speed | 2 - 3 Weeks | 3 - 5 Weeks |

| Tool Cost | $ | $$ |

| Per Unit Part Cost | $$ | $ |

Prototype Injection Molding

T1 Samples as quick as 10 days

High quality parts done fast, per your design, and to print tolerances.

Ease of our manufacturing platform

Expert support from design to molding and engineering changes

Global Network

An agile fully managed supplier network that supports your needs at every stage of the life cycle

Production Injection Molding

Cost Down Analysis

We partner with you to do cost down analysis to meet your requirements. Our global network enables Needmold to optimize for "landed costs" of the product.

Dedicated Global Team

Manufacturing Engineers, Technical Program Mgt, SQE, Tooling Engineers, Logistics Supervisors assigned to each production program.

Complete Quality Systems

APQP full program planning, PPAP, Scientific Molding, Tooling inspection, and Automation. Access to ISO 9001:2015 quality certification and manufacturing partners certified to AS9100 Rev D, ISO 13485:2016, and IATF 16949:2016

Our Injection Molding Speciality Process

Overmolding

Overmolding starts by molding a single material, typically the harder material, in a mold and then ejecting it and cleaning off the gates.

2K (two-shot) Molding

2K Molding is done in a single injection mold machine with 2 or more injection units and with a tool that has 2 cavities that rotate between molding cycles to allow for multiple material parts.

Insert Molding

Insert molding is done by placing inserts or some other material into a mold before the molding cycle.

Gas Assist Molding

Gas Assist Injection Molding is a molding process that uses pressurized gas like Nitrogen to hollow out thick sections of a plastic part during injection.

Micro-molding

Micro-molding is an injection molding process used to manufacture extremely small and precise plastic components, often with intricate geometries and tight tolerances.

Compression Molding

Compression molding is a manufacturing process that takes a premeasured amount of thermoset rubber or silicone and presses it into the required shape while it vulcanizes into its’ final material properties.

Liquid Silicone Rubber (LSR) Molding

LSR is an injection molding process that uses liquid silicone rubber to create flexible, durable, and heat-resistant components.

Multi-Component (Multi-Shot) Molding (3K Molding)

3K molding (Three-Shot Molding) is an advanced multi-material injection molding process that allows three different materials or colors to be combined into a single molded part in a single production cycle.

Injection Molding Secondary Processes

All finishes meet SPI standards

Painting and Coating

Pad Printing/Screen Printing

Laser Engraving

In-Mold Labeling (IML)

Ultrasonic Welding

Heat Staking (Inserts)

Heat Staking - Joining

Drilling and Tapping

Adhesive Bonding

Assembly

Customized Testing, Reporting, and Design Optimization

Packaging and Labeling

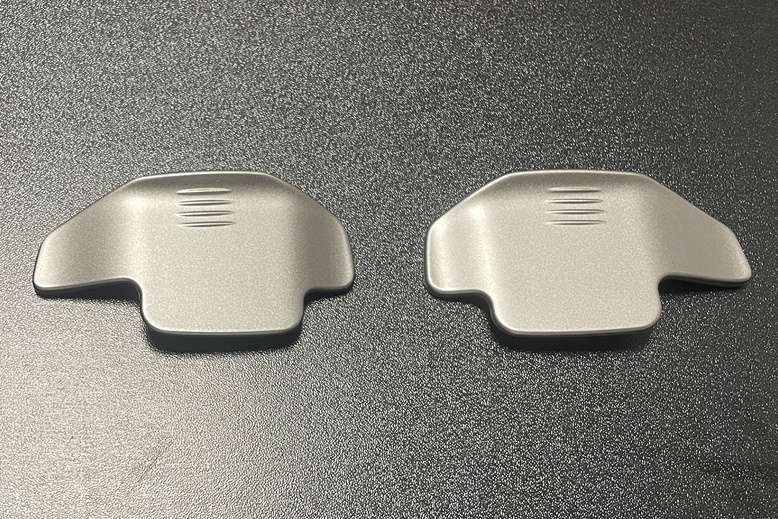

Painting and Coating

Painting enhances the aesthetics and performance of molded plastic parts. This process involves masking and preparing parts and then applying paint or specialized coatings to improve appearance, UV resistance, durability, or electrical interference.

- Improved aesthetics

- UV & chemical resistance

- More durable parts

- EMI shielding

Pad Printing/Screen Printing

Pad printing and screen printing are methods that apply logos, text, or detailed graphics onto parts. Pad printing uses a silicone pad to transfer ink from an etched plate onto the product surface, making it ideal for curved and irregular surfaces. Screen printing involves pressing ink through a mesh stencil, making it suitable for flat or cylindrical surfaces with high-opacity prints.

- High-quality graphics

- Versatility

- Durable marking

- Cost-effective

Laser Engraving

Laser engraving is a permanent marking process that uses a laser to etch or remove material from the surface of a plastic part. It is commonly used for branding, serial numbers, barcodes, and decorative elements. The high precision and durability of laser engraving make it ideal for industrial and medical applications.

- Permanence

- High precision

- No ink or chemicals

- Tamper-proof markings

In-Mold Labeling (IML)

In-mold labeling is a process where pre-printed labels or graphics are placed inside the mold before plastic injection. The label becomes permanently fused with the molded part, resulting in a seamless, durable design. This process is widely used for consumer packaging, medical devices, and back-lit keypads.

- Long-lasting graphics

- Reduced production time

- High-quality appearance

- Improved durability

Ultrasonic Welding

Ultrasonic welding is a technique that uses high-frequency vibrations to generate localized heat. It allows two plastic components to fuse together without adhesives or fasteners. It provides strong, airtight, and watertight bonds, making it ideal for automotive, medical, and electronic applications.

- Strong & reliable bonds

- No need for adhesives or fasteners

- Fast production time

Heat Staking (Inserts)

Heat staking is a process used to embed metal inserts (such as threaded bushings or pins) into plastic components. Heat is applied to the insert which then softens the plastic, allowing the insert to be pressed in securely. This method enhances the structural integrity of components that require repeated fastening.

- Enhanced strength

- Reusable fastening

- Precision placement

Heat Staking - Joining

Heat staking for joining involves softening and reshaping plastic posts or protrusions to form a secure mechanical connection between two plastic parts. It is commonly used in assemblies that require strong, non-reversible joints without additional fasteners or adhesives.

- Strong mechanical bond

- No additional fasteners

- Minimal material stress

Drilling and Tapping

Secondary machining operations can be required on molded parts to hold tighter tolerances or add threads to formed plastic parts. Fictiv can work with you to determine when this is required and provide this service for your molding program.

- Precision enhancement

- Added threads or other features

Adhesive Bonding

Adhesive bonding is a method of joining plastic parts using industrial adhesives such as cyanoacrylate, epoxy, or UV-curable adhesives. This method allows for the assembly of different materials while providing a clean and durable bond. It is often used in medical devices, consumer products, and electronics.

- Works with different materials

- Uniform load distribution

- Aesthetic bond

- Seals & insulates

Assembly

Assembly refers to the process of putting together multiple molded components to create a functional product. This can include snap-fit connections, mechanical fastening, welding, and adhesive bonding.

- Customization flexibility

- Supports complex products

- Various joining methods

- Automated or manual

Customized Testing, Reporting, and Design Optimization

NeedMold prides itself on supporting our customers’ various testing, reporting, and optimization program needs. We can develop a set of requirements and checks to ensure we are meeting your requirements for your next injection molding program. Whether you need specialized inspection and reporting or customized testing of your design, we will work with you to develop a system to provide it.

Here are some of the normal processes we support, let us know if you have others:

- APQP

- FAI

- IP/OP/QP

- PPAP

- Cpk

- Hardness

- Drop

- Leak

- Tear out

Packaging and Labeling

Packaging and labeling are essential steps in preparing finished parts for distribution. This includes protective packaging (such as blister packs, shrink wrap, or foam padding) and labeling for product identification, barcoding, and branding. Proper packaging ensures that parts remain undamaged during shipping and storage.

- Protection during transit

- Efficient inventory management

- Brand enhancement

- ARegulatory compliance

Our Injection Molding Process

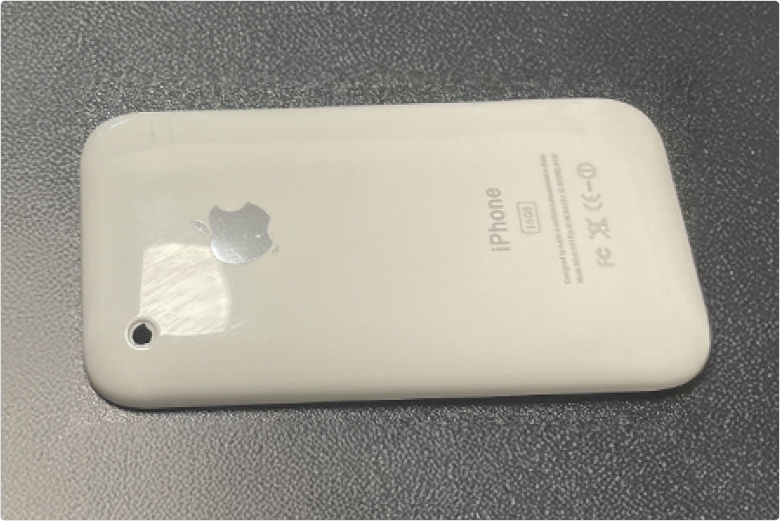

Design Validation and Production

Steel tooling, rapid lead times, and no minimums — ideal for prototyping, design validation, and bridge production.

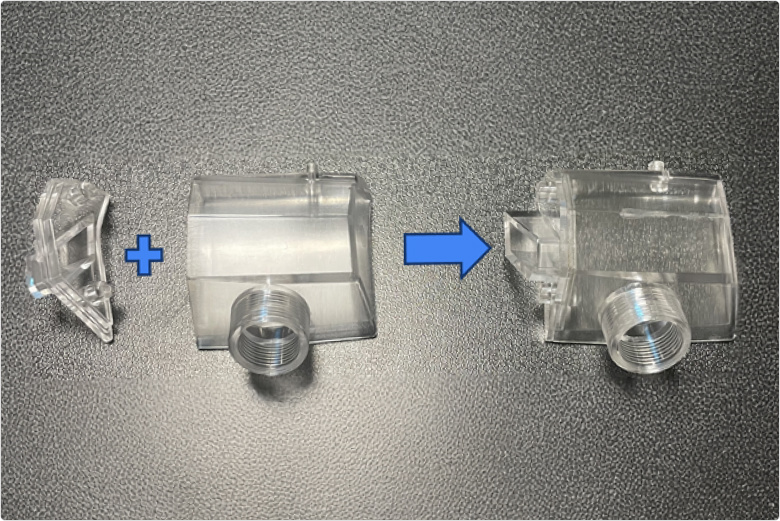

Overmolding

Whether for buttons, grips, or seals, mold rubber or silicone over an existing plastic part.

Insert Molding

Mold plastic around a preformed — often metal-threaded — insert.

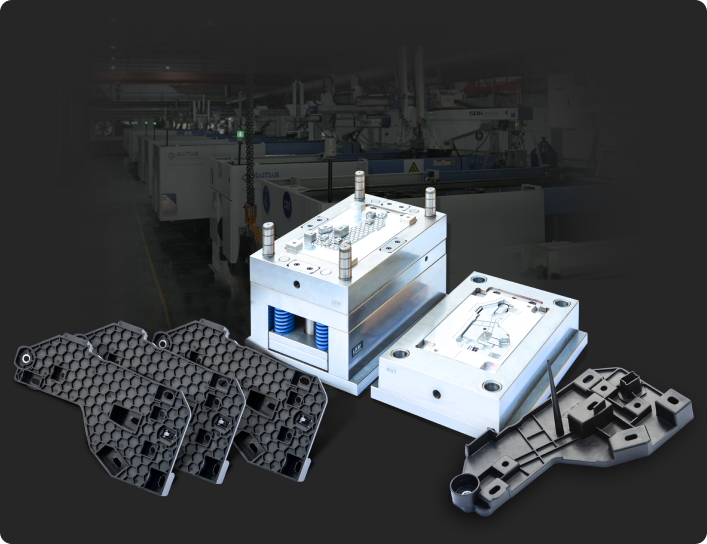

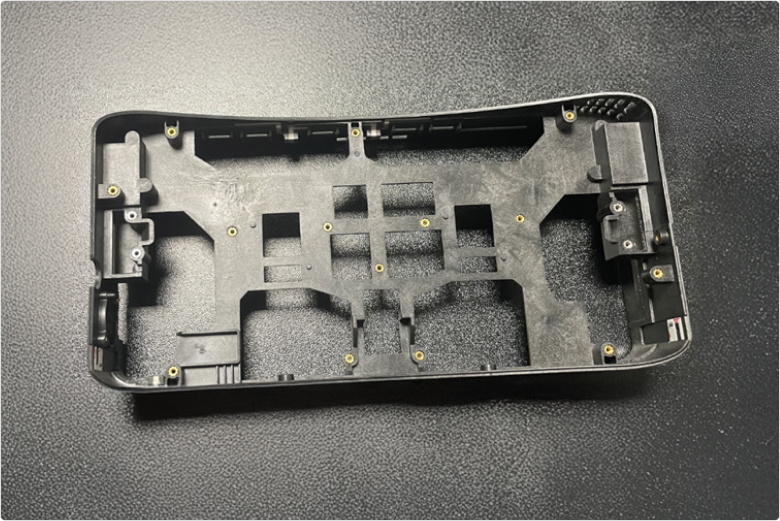

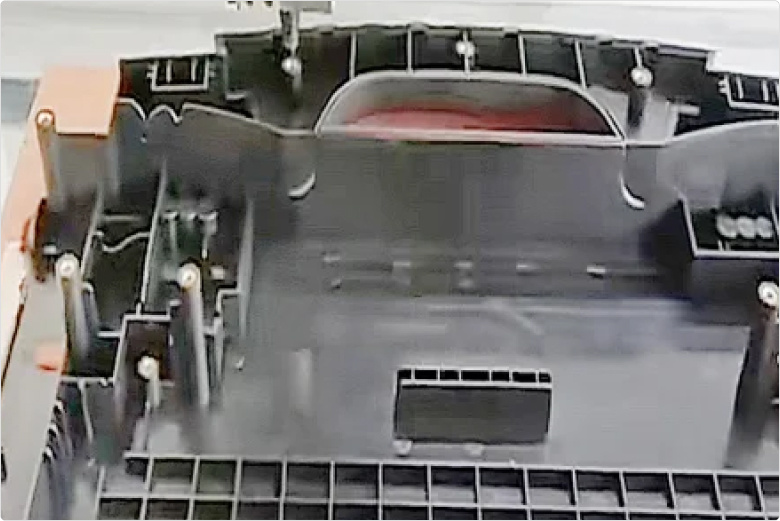

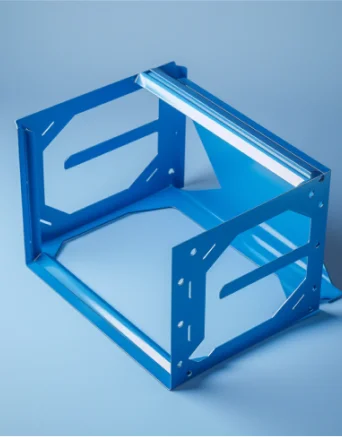

Injection Molding Parts and Tools Made By Needmold

Injection molding Service FAQs

How does Needmold protect my intellectual property?

At Needmold, we know how critical information security is, especially when working with high-value design IP. That's why we designed our platform with elite-level security and confidentiality as a top priority. From log in to file upload to part fulfillment, you can rest easy knowing that your IP is safe within our secure Digital Manufacturing Ecosystem. Read More about it here.

How long does it take to make molded parts?

Once the materials and molds are prepared and in place, the injection molding process allows for the production of several hundreds of molded parts per day.

How long will it take to make injection molding tooling?

The tooling lead time can vary depending on the complexity of the part. In some cases, it can be as quick as 10 days, while in a more complex design, it may extend to around 21 days (calendar days). For parts larger than 300mm, the lead time might be further extended due to the additional complexities involved in manufacturing larger components.

Does Needmold perform mold flow analysis before building the molds?

Needmold does not conduct mold flow analysis as a standard DFM analysis for injection molding, however, it can be done as an additional service upon request.

What DFM analyses does Needmold provide?

Injection molding is a tricky process, and one that we want to work through with our customers. This means that while we offer draft, thickness, and sink analysis on-platform for every quotation, we often provide advanced DFM in the forms of parting line visualization, side action analysis, and mold-flow analysis upon request.

At what quantity is it worth it for me to move from 3D printing my parts to injection molding them?

A part manufactured through 3D printing is orders of magnitude more expensive than the same part manufactured through injection molding, assuming the design is a fit for injection molding. As long as you produce enough of that part to offset the mold cost, it would be worth it to pursue injection molding. Needmold provides you with DFM on your design and options for mold architecture to give you the best cost-benefit balance. Request an injection molding quote for your 3D-printed part design to get a no-obligation quotation and DFM and assess your options at no cost to you. It is recommended that you get an expert involved early on in the design process if you intend to use injection molding for production. Many customers invest significant time in creating 3D-printed prototypes and making revisions without taking into account the specific manufacturing constraints associated with injection molding. This oversight can lead to wasted resources, both in terms of money and time. By providing Design for Manufacturability (DFM) guidance tailored to injection molding, Needmold can help you avoid such pitfalls, resulting in significant savings in time and costs.

Does Needmold build quick turn Aluminum molds?

Needmold has the ability to build both aluminum and steel molds.

Does Needmold charge for DFM feedback?

We believe in getting our customers the best possible parts the first time. Therefore, Needmold does not charge for DFM and we ensure that you have all of the assurances you need before you place your injection molding order.

Does Needmold provide DFM on my part design before I place an order?

We do! Not only are you able to access your DFM through the Needmold platform, but you will receive 3D visualization of the DFM feedback and be able to comment on, annotate, and discuss this feedback with a Fictiv technical project lead. All of this happens before you place your order.

Does Needmold charge an inventory fee on my molds?

Needmold does not charge any inventory fees for holding your molds, as long as you order off of the mold within 2 years. After 2 years of inactivity, Needmold will ship/destroy the mold at the customer's direction.

Once I have a mold, can I reorder from it?

Of course! Needmold will maintain your mold for 2 years after your most recent order and allow you to re-order parts for the duration of the mold life.

Does Needmold provide a no-obligations estimate for my injection molding project?

Absolutely. As long as you are able to supply project requirements and part specifications, Needmold is happy to provide a no-obligation quotation.

What is the minimum order quantity for injection molding?

Needmold is happy to offer you injection molding services with NO minimum order quantity.

Is injection molding a good option for prototyping?

Injection molding could absolutely be used for prototyping, but it depends on the project requirements. Typically, for projects that require less than 10 prototypes, injection molding may not be the most cost-effective option. We are happy to meet with you to discuss your needs and help determine if injection molding is the correct process for you.