Jul 03,2025

Unlocking the Secrets of CNC Milling Machine Parts

People who spend time on factory floors know that getting your head around a CNC milling machine is not optional-anyway anyone else curious about gear-cutting soon wishes it were.

People who spend time on factory floors know that getting your head around a CNC milling machine is not optional-anyway anyone else curious about gear-cutting soon wishes it were. These hefty mills quietly underpin most of the high-precision parts the aerospace, auto, and medical sectors now take for granted. In plain terms, the control cabinet, slide ways, spindle group, and a dozen other assemblies somehow collide math with metal in a way few earlier machines ever managed. The piece that follows gingerly prises apart that mechanical puzzle and calls each component by name. Veterans will nod along; newcomers will mark a few first-time answers. No matter which camp you belong to, knowing the guts of the mill goes a long way toward grokking how today’s factories stay fast and square.

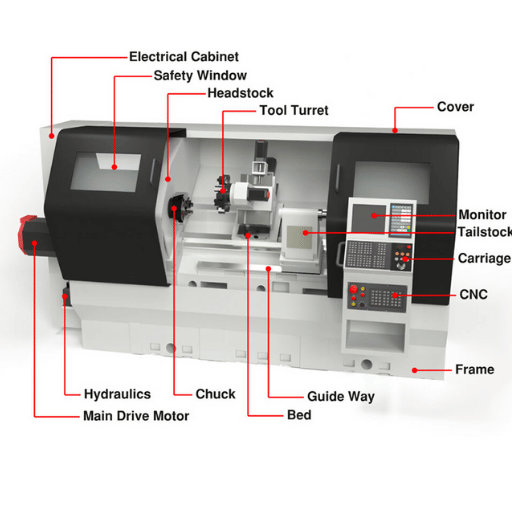

What Are the Essential Components of a CNC?

A modern Computer Numerical Control (CNC) machine is a coordinated assembly of parts that together deliver remarkable precision.

- The Controller serves as the system’s central processor; it decodes G-code instructions and dispatches real-time commands to every moving element.

- Mounted above the Machine Table, the bed locks the blank material in place, resisting vibration and keeping setup errors to a minimum.

- In the headstock, the Spindle houses a high-speed motor that spins inserts or end mills, enabling drilling, milling, and engraving with equal ease.

- Cutting Tools themselves are engineered from hardened alloys or carbide grades, their profiles designed to slice through various metals and plastics without drift.

- Movement occurs along linear X, Y, and Z rails; motors coupled to ball screws compose the Drive System that breathes motion into those axes.

- Feedback Systems of encoders and optical sensors continuously log position data, correcting course before any geometric lapse can occur.

- Finally, a Coolant System drenches the tool and workpiece with fluid, dissipating heat and flushing away chips that would otherwise gum the operation.

When every piece operates in concert, programmed geometries transfer from screen to part with repeatable accuracy, earning CNC machines their critical role on today’s factory floors.

Understanding the Machine Parts and Their Functions

Every day, tools and assemblies- simple gears, sturdy bearings, even humble fasteners- cooperate so that one piece nudges another, braces a heavy load, or quietly holds the whole frame steady.

Role of the CNC Controller in Machining

At the heart of every CNC machine sits the controller, a role akin to a planet’s central nervous system. When the unit receives a CAD-CAM file, it decodes the digital commands and then choreographs the movement of motors and the plunge of the tool bit. That choreography locks in the onscreen coordinates with split-second timing and keeps spindle speed and feed rate lined up. Engineers keep packing modern boxes with tricks- feedback loops that report position errors, algorithms that nudge power settings as metal heats, and touchscreens that shrink operators’ learning curves. All of those refinements trim waste, tighten tolerances, and open the door to parts shapes that once lived only in design sketches.

Importance of Axes in CNC Operations

In the world of CNC machining, the term axis refers to any designated line along which movement is computerized. Every distinct axis charts a separate course for either the cutting tool or the workpiece itself. Most conventional setups follow a straightforward three-part formula: an X glide for side-to-side travel, a Y sweep for in-and-out feed, and a Z plunge that handles up-and-down motion. Sophisticated configurations may tack on rotating labels-like A, B, and empower the spindle to orbit around the very part it is shaping.

Stacking these lines tends to multiply both flexibility and accuracy, a fact praiseworthy in 5-axis work that carves bevels no simple vice could reach. Aviation, automotive, and medical fields loiter near the top of the beneficiary list the moment repeatable precision becomes non-negotiable. Operating several axes at once curtails the fiddling needed to flip a blank, saving clock time and sparing the operator one more chance to misalign. In short, the multi-axial design remains a cornerstone of contemporary factory automation, quietly enabling complex profiles while helping shops stay ahead of a punishing competitive curve.

Frequently Asked Questions (FAQs)

Q: What are the main components of a CNC milling machine?

A: A typical CNC milling machine is built around five essential assemblies: the machine body, the control console, the spindle drive, the milling head turret, and the adjustable worktable. Together, these subassemblies permit highly repeatable machining by coordinating movement, rotation, and positioning with micrometer accuracy.

Q: How does a CNC milling machine differ from a CNC lathe?

A: In a CNC mill, the cutting tool maintains a fixed orientation and moves in three-dimensional space to sculpt a stationary part. Conversely, a CNC lathe spins the raw workpiece against a stationary blade, making it especially suited for producing axially symmetric profiles like shafts. This geometric distinction governs the kinds of tasks for which each machine is inherently more efficient.

Q: Can you describe the basic operation of CNC milling?

A: Computer Numerical Control milling automates the directional traversal of a rapidly rotating cutter, which progressively shears away excess material to reveal a planned contour. Step-by-step instructions encoded in G-code determine the tool path, feed rate, and depth of cut, allowing operators to transform vague engineering sketches into tangible prototypes with minimal manual intervention.

Q: What materials are commonly machined into CNC-milled components?

A: Aluminum alloys, hardened steels, and engineering plastics rank among the most routinely milled substrates, owing to their favorable machinability and mechanical properties. Manufacturers select each material according to criteria such as tensile strength, weight limitations, or environmental resistance implicit in the parts’ end use.

Q: How do CNC milling services benefit manufacturing?

A: Engineers rely on CNC milling because the technology translates digital designs into tangible components with remarkable fidelity. Beyond one-off prototypes, the process accommodates production runs that number in the thousands while minimizing operator fatigue and error.

Q: What is the role of the machine control unit in a CNC system?

A: Some technicians still call it the brains of the outfit. The machine control unit interprets the coded instructions fed to it, orchestrates every axis and spindle shift, and locks in the repeatability that manufacturers expect.

Q: What are the most common varieties of CNC milling machines?

A: Vertical CNC mills, horizontal configurations, and sophisticated five-axis models rank among the most frequently encountered varieties. Designers reach for each style depending on the complexity of the workpiece and the direction of cut required.

Q: What role does the milling head play in a CNC mill?

A: Mounted to the machine spindle, the milling head grips the cutter and spins it at high rpm. By shifting across several axes, the head sculpts the part geometry, tracing contours dictated by the digital program.

Q: Why do engineers request custom-machined parts?

A: Stock components seldom satisfy every application, so tailor-made pieces fill the gap. CNC technology commands the material precisely, enabling production runs that mirror unique drawings and thereby bolsters product performance.

Q: Why is machining precision non-negotiable?

A: Variations of even a few microns can derail assembly, so tight tolerances govern the process. Industries such as aerospace and automotive demand that every part interchange seamlessly, meaning accuracy directly safeguards safety and reliability.

Previous: Unlocking the Power of CNC Machine: A Guide to Metal CNC Machining Services

Latest News