Jul 03,2025

CNC Plasma Router Parts | CNC Machine & Table Components

You will need the correct components or materials to get the best out of your CNC machine or plasma table.

You will need the correct components or materials to get the best out of your CNC machine or plasma table. Irrespective of whether you are a novice or a veteran CNC machining expert, knowing which parts are most suitable in terms of accuracy, longevity, and cost is what gives you the edge. So, today, we will talk about the parts that play an essential role in your machine by enabling it to work correctly and giving you an excellent finish. There are some parts that every CNC owner should have, starting right from the drive systems, cutting tools, software, and enhancements. Prepare to see the quality of your machining activities improve!

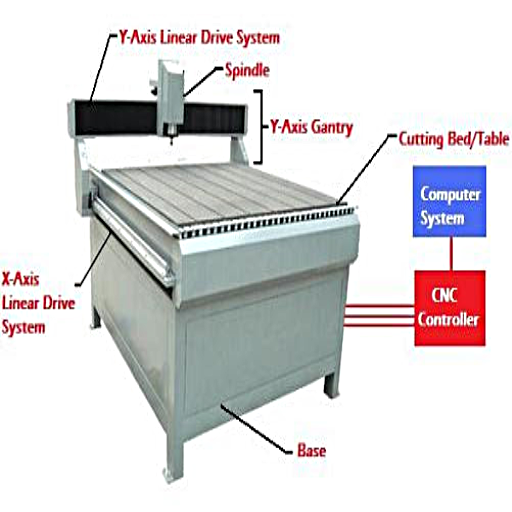

What Are the Essential CNC Router Parts?

- The spindle is considered the most essential part of the CNC machine. It is mainly used to cut, engrave, or shape material into the required size with high accuracy. A good-quality spindle machine helps attain proper work finishing.

- The Control System enables the user to regulate the performance of the CNC router, making it a precision machine. This system decodes the drawing files and guides the machine by providing displacement values.

- Router Bits are physical items that execute a workpiece’s cutting process or engraving. The choice of tools, including bits and end mills, is an aspect that one cannot afford to get wrong if there is to be a precise and clean cut.

- A Drive System is a system for moving a machine from one place to another, often allowing it to move in three directions. This feature is extremely important for the architecture as it ensures its proper operation.

- The table or Bed is where the raw material is set and lies flat in the machine while in an accurate position. The table allows for easier clamping and improves the quality of your machined parts due to the weights applied.

Concentrating on these critical modules will most likely make your CNC router work efficiently and produce professional-quality outputs.

Key Features of CNC Router Parts

- Precision and Accuracy—The Parts of the CNC machine have undergone numerous improvements to achieve precision reinforcement and enable the production of detailed designs with detailed cutting. This is done through the application of excellent specifications and the use of advanced control systems.

- Durability and Sturdiness—Every piece of a CNC router is constructed of durable hard materials such as iron and aluminum, meaning it can be used robustly for a long time without wearing out.

- Convenience—An essential aspect of most parts is similar to the ease of basic repairs regarding maintenance. Most of those parts have simple assembly or are easily dismantled to facilitate repair or cleaning.

- Options and features—CNC router parts allow the freedom to use various types of add-on items, tool-changing systems, and workpiece sizes. Hence, the CNC machine can be applied to other projects and materials.

- Motion Control –Some CNC routers are designed with ballscrews, and others have rack-and-pinion or belt drives. Still, all have controlled movements in all axes that are very smoothly executed due to the precise placement of high-tech components such as motors.

How to Choose the Right CNC Router Accessories

In case of CNC router equipment upgrades, you should evaluate the functionality of each asset for a particular project, and subsequently, if it is compatible with the unit. This includes determining the kind of materials that will be cut the most, as wood cutters and acrylic cutters are two widely integrated machining centers. End mills and drill bits are examples here; the shape of the cutting edge and its coating are modified to perform the best on the materials it was designed for.

After that, one must consider how tight the equipment’s machining tolerances and process rates should be. For some established strategies and applications, accessories like vacuum systems, their respective jigs, and sacrificial boards are required to ensure that the material does not get spoiled, aside from being able to perform tasks in a clutter-free environment. At the same time, the attachment of other spindles and complexes around them can allow more automation options.

It is also essential to look for accessories that extend the life and enhance the strength of your CNC router. Any manufacturer provides support and services like maintenance kits, vital parts, and external cooling. You can also check the gear reviews and the air conditioner evaluations to choose the one that will fit your requirements well.

Moreover, affordable prices mustn’t eliminate necessary specifications. This is because there are reasonably priced ads on packages, though purchasing and upgrading to high-quality performers has proven to reduce machine downtime. After all, they are more productive. Also, domesticated equipment designed for fabricating other equipment is best optimised when the manufacturer recommends the optimal application.

Frequently Asked Questions (FAQs)

Q: What components are essential for a CNC plasma router setup?

A: Essential components for a CNC plasma router setup include the spindle, motor, gantry, vacuum table, router kit, and dust collector. Each plays a crucial role in the machine’s overall functionality.

Q: How does a clamp kit improve the performance of CNC machining?

A: A clamp kit helps secure materials firmly onto the vacuum table, ensuring they remain stable during the routing or cutting. This stability is vital for precision in CNC oxyfuel cutting and routing operations.

Q: What is the purpose of a tool changer in CNC routers?

A: A tool changer allows for automatic switching between different tools during machining, enhancing efficiency and reducing manual intervention. It is beneficial in complex routing tasks that require multiple tools.

Q: Can I use aluminum extrusion in my CNC router projects?

A: Aluminum extrusion can be machined using a CNC router. It is commonly used due to its lightweight, durability, and ease of fabrication, especially for industrial CNC applications.

Q: What advantages does a rotary attachment provide for CNC routers?

A: A rotary attachment allows CNC routers to engrave or cut cylindrical objects by rotating them during machining. This expands the machine’s capabilities and enables creative applications beyond flat surfaces.

Q: How can I maintain my CNC router to extend its machine life?

A: Regular maintenance, including cleaning the dust collector, lubricating moving parts, and checking the alignment of the gantry and spindle, is essential for extending the machine life of your CNC router. Additionally, using coolant during routing can help reduce wear on tools.

Q: What is G-code, and how is it relevant to CNC routing?

A: G-code is the programming language that controls CNC machines, including routers. It contains commands instructing the machine on movement, tool changes, and other operations necessary for accurately routing or cutting materials.

Q: What role does a dust collector play in CNC machining?

A: A dust collector is crucial for maintaining a clean workspace by removing debris and dust produced during the routing process. This improves visibility, helps protect the machine’s components, and extends their lifespan.

Q: What materials can I effectively cut with a CNC plasma router?

A: A CNC plasma router is ideal for cutting various materials, including metals such as steel and aluminum, plastics, and wood. Its versatility makes it suitable for industrial applications, including CNC oxyfuel cutting.

Q: What is the benefit of using a t-slot table in CNC routing?

A: A t-slot table provides a flexible and adjustable work surface that allows users to securely attach fixtures and clamps. This ensures that workpieces are held firmly during routing, enhancing precision and efficiency in the machining process.

Previous: CNC Machine Truck Parts and Car Parts

Next: Custom CNC Wood Parts & Components | CNC Router & Machine

Latest News