Jul 03,2025

CNC Machine Truck Parts and Car Parts

Usually, for huge and heavy-end vehicles, two main factors are of great importance: performance and reliability, which are must-haves.

Usually, for huge and heavy-end vehicles, two main factors are of great importance: performance and reliability, which are must-haves. Whether you are the manager of a fleet or keeping your vehicle in good condition and running, the availability of spare parts is essential for business operations. The truck spares that have been CNC machined have made it possible to produce parts that are made to great precision and give a long service life with the help of customization. However, some problems arise when trying to pick the best elements from the large number in the market that meet your desires and do not compromise. Therefore, from this post, we will learn about the universe of CNC truck parts, where the benefits, the main features all should pay attention to and the guidelines for smart consumerism are included. If you are making up your mind to beef up your truck while stringing up, be sure not to miss the content of this help!

What are CNC Truck Parts and How Do They Work?

What are CNC Truck Parts and How Do They Work?

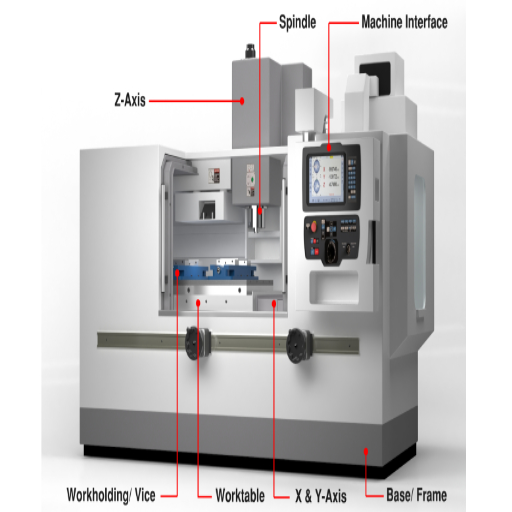

CNC truck parts are Computer Numerical Control (CNC) technology machine components. It involves using computer software with all the commands set to specify where the cutting of the item should be done with the aid of certain materials like plastics or metals. These parts are engineered for an incredible fit, last long, and perform well in automotive environments. With the onset of lazer-cutting metals and other engineering systems there is no going back to the days when professionals, their staff ad other or every mechanical personnel had to take back for cuts or machine alterations for different parts of the truck which was not in size or too a larger or smaller cut than had been planned. The application of this technology has also allowed for the development of intricate yet efficient designs while adhering to high standards of quality and precision.

The Role of Precision in CNC Truck Parts

Targeting precision is integral when producing different elements of a CNC lorry or any other vehicle that conform to the correct values and standards. With today’s capabilities, tolerance as narrow as ±0.001 inch or smaller can be easily achieved in CNC machining. This outstanding performance is dedicated to catering to the needs of high-performance locomotives. In addition to this reduction in wear, the said work guarantees increased longevity of truck systems since all the parts are expected to fit and operate neatly with minimal or no space.

Progressed cnc machining practices that have cropped up around accuracy improvement include application of AI software in computerized controls in conjunction with continuous validation of the quality of the parts made. Forecasts, as per the report, suggest that the market for CNC machining across the globe will grow with a CAGR of over 7.3% during the forecast period 2021-2030, and most of this growth will be fuelled by the demand for automotive components, which are required to be highly accurate in their dimensions. This shows the movement recognizes the use of precision manufacturing in the trucking sector as meeting goals for performance, safety, and economy.

When implemented incorrectly, however, exactness in product manufacture can result in CNC machined parts that must be scrapped, increasing the net costs. Conversely, when produced with accuracy by CNC machines, defects in truck components and their use in trucks are much controlled, thereby reducing levels of defects. This includes all categories of defects or flaws that result from errors in the part, such as design errors or machining errors.

Benefits of Using CNC for Truck Spare Parts Production

- High Accuracy and Uniformity

Besides the convenience of avoiding human error, CNC machining can also produce lorry parts with hard-to-reach consistency and precision. Any deviations are, therefore, avoided, resulting in a minor margin of safety and perfect vehicle performance.

- Enhancement of Efficiency and Work Ability

Modern CNC technology allows them to be used continuously for long shifts without compromising the accuracy of work. This has enabled the production of truck parts to move at faster rates, as well as meeting deadlines and other such activities.

- But it Is Still Economical in the End

However, establishing the CNC setup may require a mammoth budget, but it turned out to be very economical in the end. Achieving very high levels of quality in engineered parts by eliminating or reducing material waste and the need to redo poor-quality products makes CNC machining manufacturing very cost-effective.

- Higher Resilience of the Parts

CNC machining enhances the reliability of truck parts by facilitating the use of better quality materials and technology rather than only using cheaper materials. All designed truck parts are thus setup in the CNC machining techniques to withstand heavy loads, extreme temperatures, surface abrasions, and continuous use.

- Versatility and Scalability of the Process

The ease of using CNC programming means there is little trouble making changes in line with customer specifications and increasing the volume of production. Market-made parts, such as versions according to the designs offered by the customer, can be produced immediately or in mass quantities, depending on the requirements, without any problems in making the product.

Frequently Asked Questions (FAQs)

Q: What are the advantages of using CNC machining for automotive parts?

A: CNC machining offers high precision and consistency when manufacturing automotive parts. The advanced CNC technology allows for the production of complex parts with tight tolerances, ensuring that each component meets the required specifications for quality and performance.

Q: What materials are commonly used in CNC machining for car parts?

A: Common materials include aluminum alloys, steel, and various metals suitable for part machining. Aluminum is favored for its lightweight and strength properties, making it ideal for automotive applications.

Q: How does the CNC machining process work for truck parts?

A: The CNC machining process involves programming a computer to control the machinery that shapes the metal parts. This includes milling and turning operations to create precision components used in truck assembly, ensuring high-quality manufacturing.

Q: What are CNC aluminum parts, and why are they used in the automotive industry?

A: CNC aluminum parts are aluminum components produced using CNC machining methods. They are used in the automotive industry due to their lightweight nature, corrosion resistance, and ability to achieve high precision in part manufacturing.

Q: Can I get custom car parts made through CNC machining?

A: Many CNC machining services offer OEM custom solutions for car parts. This allows for creating unique components tailored to specific automotive applications, enhancing vehicle performance and customization.

Q: What is precision machining, and how does it relate to automotive parts?

A: Precision machining refers to creating parts with high accuracy and tight tolerances. In the automotive industry, precision machining is crucial for producing engine parts, turning parts, and other components that require exact specifications for optimal functionality.

Q: What role do CNC machinists play in manufacturing automotive parts?

A: CNC machinists are skilled professionals who operate CNC machinery to create parts with CNC machining. They are responsible for programming the machines, setting up tools, and ensuring that the parts produced meet quality standards in the automotive sector.

Q: What are the benefits of using CNC precision machining for metal parts?

A: The benefits of CNC precision machining include improved accuracy, reduced waste, and faster production times. This is particularly important for metal parts in the automotive industry, where precision and reliability are paramount.

Q: How does sheet metal fabrication fit into the production of automotive parts?

A: Sheet metal fabrication is a vital part of the automotive parts process, allowing for the creation of various components such as chassis, panels, and brackets. CNC machinery is often used to ensure precision and efficiency in manufacturing these parts.

Previous: Mastering CNC Turned Parts: Precision and Efficiency in Parts Manufacturing

Next: CNC Plasma Router Parts | CNC Machine & Table Components

Latest News