Jul 03,2025

Mastering CNC Turned Parts: Precision and Efficiency in Parts Manufacturing

Fulfilling demands for high-quality precision parts and components at lower manufacturing costs is a challenge for many companies working in today`s manufacturing industry.

Fulfilling demands for high-quality precision parts and components at lower manufacturing costs is a challenge for many companies working in today`s manufacturing industry. This is where the significance of CNC turned parts comes in as the No. 1 Solution in modern machining, where accuracy and efficiency are unmatched. The article basically talks about why CNC turning is essential in parts manufacturing, what technology backs it up, and how it is beneficial. Be it a manufacturer, engineer, or an individual interested in utilizing such precision techniques, this well-detailed guide will throw light upon the rather complicated CNC turning process along with its other attractive features.

What is CNC Turning and How Does it Work?

One of the strategies to obtain CNC turned parts is the CNC turning method. It is a tool which is used, for example, to machine the outside of required shapes, i.e., cylindrical inner and outer shells. It also requires securing the piece of work within a rotating chuck and applying a cutting tool, which remains in a stationary position, with the effect on the dimensions of the workpiece. The process and mechanisms are regulated and automatically operated using a system called Computer Numerical Control (CNC), which enables the use of program codes for cutting and shaping tools with high precision. Hence, the high confidence, uniformity, and quicker pace of part production. For this reason, CNC-operated lathes can be found almost in every industry dealing with high-precision parts with thin walls and complex norms, such as automotive, aviation, and medicine.

Understanding the CNC Turning Process

CNC turning describes a process of subtractive manufacturing, whereby a particular workpiece rotates while a cutting tool is able to shape the piece into the required design, mostly on a lathe.

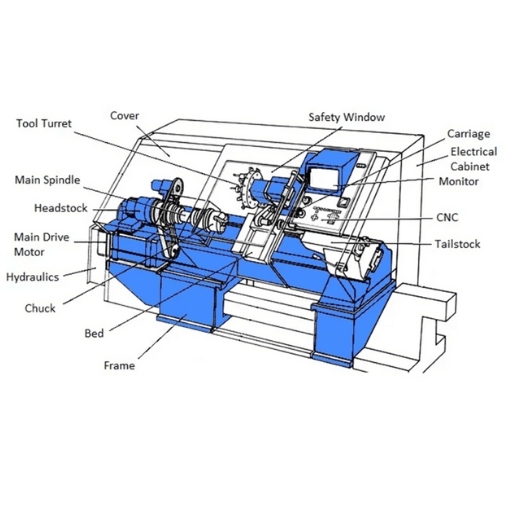

Key Components of CNC Turning Machines

CNC turning machines are comprised of various parts, and these components all work together to deliver high accuracy and high performance. These components include:

|

Component |

Role |

|---|---|

|

Spindle |

Rotates workpiece |

|

Chuck |

Grips workpiece |

|

Turret |

Holds cutting tools |

|

Control Panel |

Interface for programming |

|

Cutting Tools |

Performs machining tasks |

|

Cooling System |

Prevents overheating |

|

Bed |

Supports structure |

|

Headstock |

Houses spindle drive |

|

Tailstock |

Supports long parts |

|

Drive System |

Moves tools/workpiece |

|

Feedback System |

Ensures precision |

|

Display Unit |

Shows machine status |

Nowadays, computerized numerically controlled (CNC) lathes are one of the most important elements of the machine shop operations, especially due to the presence of integrated computers and sensors that allow them to work even more efficiently, thanks to real-time monitoring and correction of parameters. These developments contribute towards increasing the accuracy of the manufacture, saving material, decreasing the number of idle intervals and, hence, making any CNC turning indispensable in industrial production where parts’ demand is high and complex machining is also required.

What Sets CNC Turning Apart from Other Machining Techniques

The primary feature of CNC Turning that differentiates it from other cutting methods is the rotation of the workpiece against the fixed cutting tool. Therefore, it is specifically appropriate for the making of symmetrical and or cylindrical workpieces. This differs from processes such as milling or drilling, which involve moving or rotating the tool.

A precise table displaying key distinctions is provided below:

|

Parameter |

CNC Turning |

CNC Milling |

Drilling |

Grinding |

|---|---|---|---|---|

|

Workpiece |

Rotates |

Stationary |

Stationary |

Stationary |

|

Tool |

Stationary |

Rotates |

Rotates |

Rotates |

|

Shape |

Cylindrical |

Complex |

Holes |

Smooth |

|

Precision |

High |

High |

Moderate |

Ultra-high |

|

Application |

Shafts, Rods |

Pockets, Slots |

Holes |

Finishing |

|

Material |

Metals, Plastics |

Metals, Plastics |

Metals |

Metals |

Frequently Asked Questions (FAQs)

Q: What are precision CNC turning services, and how do they enhance parts manufacturing?

A: Precision CNC turning services employ computer-controlled lathes to generate components with remarkably tight tolerances. By automating the path and speed of the cutting tool, shops can repeat complex geometries hour after hour while still serving stringent aerospace or medical specifications.

Q: How does CNC turning differ from CNC milling in parts manufacturing?

A: CNC turning shapes a stationary metal blank by rotating it against a fixed cutting tool; the resulting profile is nearly always cylindrical. Milling, by contrast, keeps the workpiece still and sends a spinning cutter along three or more axes, enabling flat, pocketed, or contoured surfaces. Each process, therefore, excels at genres of geometry that the other finds cumbersome.

Q: What types of materials can be used in precision turned parts?

A: High-volume job shops routinely spin 1018 steel, 6061 aluminum, and commercially pure titanium, but plastics such as acetal and peek are also common on the schedule. Material choice is often driven by attribute trade-offs: machinability today, corrosion resistance tomorrow, fatigue strength next quarter. Every raw bar speaks first to the application before a single pixel hits the screen.

Q: Why is live tooling on CNC lathes so valuable in modern shops?

A: Built-in cutters and driven spindles let a single setup face, mill, drill, or tap a part, which saves the gamble of transferring the blank between machines. That streamlining cuts idle time, keeps tolerances tight, and turns out complex profiles in one quick run.

Q: What job does the lathe spindle perform beyond just spinning stock?

A: The main spindle anchors the work and spins it at controlled speeds, serving as the steady foundation from which tools claim metal. Balanced rotation translates small commands into precise movements, letting chips fall where the drawing says they should.

Q: Why do manufacturers favor precision CNC turning for large production runs?

A: High-volume workhorses, modern CNC lathes marry advanced automation with repeatable accuracy. Once calibrated, a single machine can churn out thousands of identical components without drifting from the specified tolerances, thus streamlining both output and quality control.

Q: What role does surface roughness play in the utility of turned components?

A: A turned parts finish impersonates its calling card, courting the eye of an observer and the judgment of engineers alike. Smoother surfaces reflect light more evenly, minimize wear during motion, and can even dictate how well coatings or adhesives bond to the substrate.

Q: How do machinists leverage CNC lathes to craft non-standard components?

A: Programmers script a sequence of tool motions, speeds, and depths that a spooling workpiece obediently follows. The result is a one-off profile-shoulder grooves, eccentric bossing, or custom threading that would stump a conventional turret lathe, satisfying the quirkiest customer specifications.

Q: What factors determine the choice of cutting tools in CNC turning?

A: Selecting a cutting tool for CNC turning begins with the workpiece material; steel, aluminum, and hardened alloys each demand their own insert grade. Surface-finish requirements further refine the decision; a mirror-like smoothness may call for a finer-grade carbide or ceramic edge. Part geometry and the planned machining sequence also matter- wider shoulders or narrow grooves often require specialized geometries to reach every corner. Finally, tool life considerations and overall production economy nudge the engineer toward either coated inserts for longer runs or economy blades for short runs.

Previous: Expert Guide to CNC Replacement Parts: Maximizing Your Machine’s Lifespan

Latest News